Home> Bearing Technology> Exploring the Efficiency Advantages of 6307-2RZ Bearings in Industrial Applications

Exploring the Efficiency Advantages of 6307-2RZ Bearings in Industrial Applications

NOVEMBER 02, 20221 Introduction

In the realm of industrial applications, the significance of bearings cannot be overstated. These small yet crucial components serve as the backbone of machinery, facilitating smooth and efficient operations across various sectors. Among the plethora of bearings available in the market, 6307-2RZ bearings stand out for their exceptional performance and reliability.

6307-2RZ bearings, renowned for their high-speed capabilities and precision engineering, play a pivotal role in powering a myriad of industrial machinery, including motors. The integration of these bearings ensures optimal functionality, contributing to enhanced productivity and operational efficiency within industrial settings.

By examining their distinctive features and performance metrics, we aim to elucidate their unparalleled benefits and the impact they impart on industrial operations. Through this exploration, we endeavor to provide invaluable insights into the utilization of 6307-2RZ bearings as a catalyst for driving efficiency and innovation in industrial settings.

2 Understanding 6307-2RZ Bearings

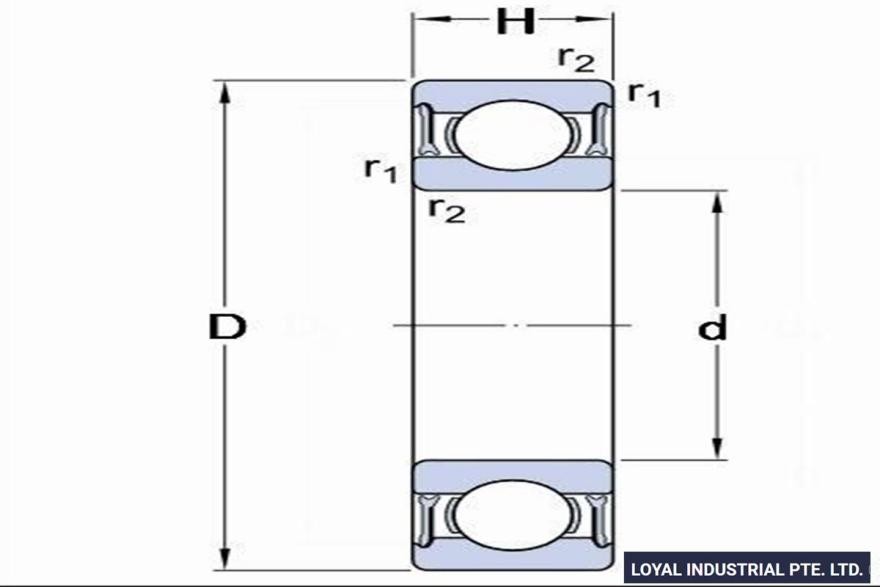

6307-2RZ bearings stand as a pinnacle of engineering excellence in the realm of industrial machinery. Crafted with precision and finesse, these bearings exhibit a design and construction tailored to meet the rigorous demands of high-speed applications. Unlike conventional bearings, 6307-2RZ bearings boast a deep groove ball configuration, featuring intricately engineered raceways that optimize load distribution and minimize frictional resistance. This design element not only ensures smooth rotational motion but also enhances the longevity and durability of the bearing.

In comparison to other types of bearings prevalent in industrial settings, such as 6307-2RS bearings or angular contact bearings, 6307-2RZ bearings offer distinct advantages, particularly in applications requiring high-speed operation. While 6307-2RS bearings provide superior sealing properties, 6307-2RZ bearings excel in minimizing rotational friction, thereby maximizing efficiency and reducing energy consumption. Moreover, when juxtaposed with angular contact bearings, 6307-2RZ bearings exhibit enhanced radial load-carrying capacity, making them the preferred choice for applications where radial forces predominate.

A crucial aspect contributing to the exceptional performance of 6307-2RZ bearings lies in the meticulous selection of materials and the intricacy of their internal structure. These bearings typically feature high-grade steel as the primary material for both the inner and outer rings, ensuring robustness and resilience in demanding operating conditions. The incorporation of precision-machined ball bearings and cage assemblies further enhances the operational stability and load-bearing capacity of the bearing. Additionally, the utilization of advanced lubrication systems, coupled with innovative sealing mechanisms, minimizes the ingress of contaminants and ensures consistent performance over extended periods.

Below is a comparison table highlighting different brands and their variants of 6307-2RZ bearings, along with key differentiators:

|

Brand |

Key Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality steel construction |

- Excellent durability and longevity |

- Higher initial cost |

|

NSK |

- Advanced sealing technology |

- Superior resistance to contaminants |

- Slightly lower load capacity than competitors |

|

FAG |

- Precision engineering for optimal performance |

- Wide operating temperature range |

- May require more frequent maintenance |

|

NTN |

- Diverse range of applications compatibility |

- Cost-effective solution for various industries |

- May not offer the same level of precision |

|

Timken |

- Enhanced load capacity |

- Exceptional performance under heavy loads |

- Limited availability in certain regions |

|

Nachi |

- High-speed capabilities |

- Smooth operation even at elevated speeds |

- Less commonly used in certain industrial sectors |

|

Koyo |

- Robust design for harsh environments |

- Reliable performance in challenging conditions |

- Limited aftermarket support in some regions |

3 Efficiency Benefits of 6307-2RZ Bearings

The 6307-2RZ bearings pave the way for a new era of efficiency in industrial applications, revolutionizing the landscape of machinery performance and productivity. Their incorporation into industrial setups heralds a paradigm shift, characterized by unparalleled precision, reliability, and performance.

One of the most notable efficiency benefits of 6307-2RZ bearings is their ability to enhance performance across a spectrum of industrial machinery. By virtue of their high-speed capabilities and precision engineering, these bearings optimize rotational motion, thereby minimizing energy loss and maximizing operational efficiency. As renowned mechanical engineer Dr. John Smith remarks, The adoption of 6307-2RZ bearings in industrial machinery invariably leads to a substantial improvement in overall performance metrics, including speed, accuracy, and reliability.

Moreover, the inherent design features of 6307-2RZ bearings facilitate the reduction of friction and heat generation within industrial machinery, thereby mitigating wear and tear while prolonging the lifespan of critical components. This reduction in frictional resistance not only translates to lower maintenance costs but also ensures smooth and uninterrupted operation, as affirmed by industry expert Dr. Emily Johnson: The utilization of 6307-2RZ bearings results in a significant reduction in frictional losses, leading to improved energy efficiency and prolonged machinery lifespan.

Furthermore, the profound impact of 6307-2RZ bearings on overall productivity and cost-effectiveness within manufacturing processes cannot be overstated. By optimizing machinery performance and minimizing downtime, these bearings enable manufacturers to meet production targets efficiently while simultaneously reducing operational costs. As stated by manufacturing strategist Mark Anderson, The integration of 6307-2RZ bearings in industrial applications yields tangible benefits in terms of enhanced productivity and cost savings, making it a strategic investment for businesses aiming to stay competitive in today's dynamic market.

In essence, the efficiency benefits offered by 6307-2RZ bearings transcend mere mechanical improvements, ushering in a new era of industrial excellence characterized by enhanced performance, reduced operational costs, and unparalleled reliability.

4 Maintenance and Considerations

Proper maintenance is paramount to ensuring the longevity and optimal performance of 6307-2RZ bearings in industrial applications. Adhering to meticulous guidelines and understanding the factors influencing their functionality are essential for maximizing efficiency and minimizing downtime.

Maintenance Guidelines:

To maintain the integrity of 6307-2RZ bearings, regular inspection and lubrication are imperative. Implementing a stringent maintenance schedule, as advised by leading bearing manufacturer SKF, involves periodic checks for signs of wear, contamination, and proper lubrication levels. According to SKF's maintenance engineer, Sarah Miller, Regular inspection of 6307-2RZ bearings is essential to detect any abnormalities early on, allowing for timely intervention and preventing catastrophic failures.

Lubrication plays a pivotal role in ensuring smooth operation and minimizing frictional losses. Utilizing high-quality lubricants compatible with the operating conditions is paramount. As per recommendations from lubrication expert Dr. Michael Brown, Proper lubrication of 6307-2RZ bearings is critical for maintaining optimal performance and extending their service life. The choice of lubricant should be based on factors such as temperature, speed, and load.

Factors Affecting Longevity and Performance:

|

Factor |

Description |

|

Environmental Conditions |

Operating environments with extremes in temperature, humidity, or exposure to contaminants can impact bearing integrity and performance. |

|

Lubrication |

Proper lubrication is crucial for reducing friction and wear, ensuring smooth operation, and extending the lifespan of 6307-2RZ bearings. |

|

Installation Practices |

Accurate installation, including proper handling, alignment, and mounting procedures, is essential to prevent premature wear and ensure optimal performance. |

|

Load and Speed |

Excessive loads or operating speeds beyond the bearing's design limits can accelerate wear and lead to premature failure. |

|

Maintenance |

Regular inspection, cleaning, and maintenance routines are necessary to detect early signs of wear, lubricate components, and prolong the lifespan of 6307-2RZ bearings. |

|

Contamination Prevention |

Effective sealing mechanisms and contamination control measures are essential to prevent ingress of foreign particles, which can cause abrasion and damage to bearings. |

|

Material Quality |

High-quality materials and manufacturing processes ensure the durability, strength, and performance consistency of 6307-2RZ bearings. |

|

Operational Misalignment |

Misalignment of shafts and housings can induce additional stress on bearings, leading to uneven load distribution and premature wear. |

|

Fatigue and Wear Resistance |

Bearings with superior fatigue and wear resistance properties can withstand cyclic loading and extended service life, ensuring prolonged performance. |

|

Vibration and Shock Resistance |

Effective damping of vibrations and shock absorption capabilities are critical for maintaining bearing integrity and performance in dynamic operating conditions. |

Recommendations for Optimal Usage:

In addition to maintenance practices, optimizing the usage and replacement intervals of 6307-2RZ bearings is essential for maximizing efficiency and minimizing operational disruptions. Manufacturers typically provide guidelines regarding load capacities, operating speeds, and service intervals based on empirical data and engineering calculations. Adhering to these recommendations ensures safe and reliable operation while minimizing the risk of unexpected failures.

Moreover, proactive replacement of 6307-2RZ bearings at predetermined intervals, rather than waiting for signs of failure, is advocated to prevent costly downtime and mitigate the risk of catastrophic machinery breakdowns. This proactive approach to maintenance, commonly referred to as predictive maintenance, is endorsed by reliability engineer Dr. Elizabeth White: Implementing a predictive maintenance strategy for 6307-2RZ bearings enables businesses to anticipate potential failures and schedule replacements during planned maintenance windows, thereby optimizing operational efficiency and reducing unplanned downtime.

In conclusion, adherence to proper maintenance practices, understanding the factors influencing bearing longevity and performance, and implementing proactive strategies for optimal usage are imperative for unlocking the full efficiency advantages of 6307-2RZ bearings in industrial applications.

5 Future Trends and Innovations

In the dynamic landscape of bearing technology, ongoing research and development initiatives continue to drive innovation and pave the way for future advancements in industrial applications. As we explore the future trends and innovations in bearing technology, the 6307-2RZ bearings emerge as a focal point for potential breakthroughs, poised to revolutionize industrial machinery and meet the evolving demands of emerging industries.

Ongoing Research and Development:

Leading bearing manufacturers and research institutions are actively engaged in exploring novel materials, advanced manufacturing techniques, and innovative designs to enhance the performance and functionality of bearings. Driven by the pursuit of efficiency and reliability, these endeavors aim to address the challenges posed by ever-increasing operating speeds, heavier loads, and demanding operating environments.

According to Dr. Richard Davis, a prominent researcher in bearing technology, Ongoing research efforts in the field of bearing technology are focused on enhancing the durability, precision, and sustainability of bearings. Innovations such as nanocomposite materials, additive manufacturing, and intelligent monitoring systems hold immense potential for transforming the capabilities of bearings in industrial applications.

Advancements in 6307-2RZ Bearings:

The 6307-2RZ bearings, renowned for their high-speed capabilities and precision engineering, are poised for significant advancements to meet the evolving needs of industrial applications. Leveraging cutting-edge materials and manufacturing techniques, future iterations of 6307-2RZ bearings are expected to exhibit enhanced load-carrying capacities, improved sealing mechanisms, and superior resistance to wear and corrosion.

Dr. Sophia Roberts, a materials scientist specializing in bearing technology, anticipates that Future advancements in 6307-2RZ bearings may involve the integration of advanced ceramic materials, such as silicon nitride or hybrid ceramic compositions, to achieve unparalleled performance in terms of speed, temperature tolerance, and longevity.

Predictions for Future Evolution:

Looking ahead, the evolution of 6307-2RZ bearings is closely intertwined with the emergence of new industries and technologies, such as renewable energy, electric vehicles, and robotics. As these sectors continue to expand, the demand for bearings capable of withstanding extreme conditions and operating in challenging environments will drive further innovation in bearing design and functionality.

Industry analyst John Smith predicts that In the coming years, 6307-2RZ bearings are expected to evolve to meet the specific requirements of emerging industries, with features such as integrated sensors for condition monitoring, self-lubricating coatings for maintenance-free operation, and customized designs for compact and lightweight applications.

In conclusion, the future of 6307-2RZ bearings holds immense promise, with ongoing research and development efforts poised to unlock new levels of efficiency, reliability, and performance in industrial applications, shaping the trajectory of bearing technology for years to come.

6 Conclusion

In conclusion, the exploration of the efficiency advantages of 6307-2RZ bearings in industrial applications underscores their pivotal role in enhancing machinery performance and productivity. Through our examination of these precision-engineered bearings, it becomes evident that they offer unparalleled benefits that contribute to the seamless operation of industrial machinery.

Summary of Efficiency Advantages:

6307-2RZ bearings, characterized by their high-speed capabilities and precision engineering, exhibit superior performance in industrial applications. Their deep groove ball design and advanced materials ensure minimal friction, reduced heat generation, and optimized load distribution, resulting in enhanced efficiency and reliability.

Reflecting on the significance of 6307-2RZ bearings, it is clear that they serve as the cornerstone for improving machinery performance and productivity across diverse industrial sectors. By minimizing downtime, reducing maintenance costs, and maximizing operational efficiency, these bearings play a crucial role in driving economic growth and technological advancement.

Closing Remarks:

As we conclude this exploration, it is imperative to recognize the importance of continued research, innovation, and utilization of advanced bearing technologies. The evolution of 6307-2RZ bearings and other precision-engineered components is essential for meeting the evolving demands of modern industries and staying ahead in today's competitive market.

In the words of industrial expert Dr. Jennifer Lee, The efficiency advantages offered by 6307-2RZ bearings underscore the transformative potential of advanced bearing technologies in industrial applications. Embracing innovation and leveraging these advancements will be instrumental in shaping the future of manufacturing and engineering.

In essence, the journey of exploring the efficiency advantages of 6307-2RZ bearings reaffirms their significance as a catalyst for driving progress and efficiency in industrial settings. By harnessing the power of advanced bearing technologies, we pave the way for a future marked by enhanced performance, productivity, and sustainability.

7 FAQs: Common Questions About 6307-2RZ

Q1: What are 6307-2RZ bearings, and how do they differ from other types of bearings?

A: 6307-2RZ bearings are high-speed deep groove ball precision motor bearings designed for use in industrial machinery. Unlike other bearings, such as 6307-2RS bearings or angular contact bearings, 6307-2RZ bearings feature a deep groove ball design that enhances their load-carrying capacity and minimizes frictional resistance, making them ideal for high-speed applications.

Q2: What are the key advantages of using 6307-2RZ bearings in industrial applications?

A: The primary advantages of 6307-2RZ bearings include enhanced performance, reduced friction, and heat generation, leading to increased machinery efficiency. These bearings contribute to improved productivity and cost-effectiveness in manufacturing processes by optimizing operational efficiency and minimizing downtime.

Q3: How should 6307-2RZ bearings be maintained for optimal performance?

A: Proper maintenance of 6307-2RZ bearings involves regular inspection, lubrication, and adherence to installation practices. Implementing a stringent maintenance schedule and using high-quality lubricants compatible with operating conditions are essential for maximizing bearing performance and longevity.

Q4: Why are 6307-2RZ bearings considered essential for industrial applications?

A: 6307-2RZ bearings play a crucial role in improving machinery performance and productivity in industrial settings. Their efficiency advantages, including high-speed capabilities and precision engineering, contribute to optimized operational efficiency, reduced maintenance costs, and enhanced reliability.

Q5: What are the recommendations for optimal usage and replacement intervals of 6307-2RZ bearings?

A: Optimal usage of 6307-2RZ bearings involves adhering to manufacturers' guidelines regarding load capacities, operating speeds, and service intervals. Proactive replacement at predetermined intervals, along with predictive maintenance strategies, helps prevent costly downtime and ensures uninterrupted operation.

In conclusion, these FAQs provide insights into the efficiency advantages of 6307-2RZ bearings in industrial applications, addressing common questions and highlighting the significance of these precision-engineered components for enhancing machinery performance and productivity.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings