Home> Bearing Technology> High-Quality Performance: Exploring the 6307-2RZ Bearing for European Machinery

1 Introduction

In the intricate world of machinery, bearings play a pivotal role, serving as crucial components that facilitate motion and reduce friction. Among these, the 6307-2RZ bearing stands out as a hallmark of precision engineering and high-quality performance. As we delve into the realm of European machinery, understanding the significance of this bearing becomes paramount.

|

Definition and Function of Bearings in Machinery

|

At its core, a bearing is a mechanical element designed to enable rotational or linear movement, typically between two parts. In machinery, bearings facilitate the smooth operation of rotating shafts, axles, or other moving parts by reducing friction and supporting loads. Without bearings, the efficiency and reliability of machinery would be severely compromised.

|

|

Importance of High-Quality Performance in European Machinery

|

European machinery has long been synonymous with precision, reliability, and uncompromising quality standards. In this context, the performance of every individual component, including bearings, is of utmost importance. The 6307-2RZ bearing, renowned for its exceptional precision and durability, aligns perfectly with the rigorous demands of European machinery manufacturers. Its ability to withstand high speeds, heavy loads, and harsh operating conditions makes it indispensable in various industries, ranging from automotive to aerospace.

|

|

Overview of 6307-2RZ Bearing as a Key Component

|

The 6307-2RZ bearing belongs to the category of deep groove ball bearings, characterized by its optimized internal geometry and sealing mechanism. Its designation, 6307, indicates its specific dimensions and series, while 2RZ denotes its particular type of sealing arrangement, which provides enhanced protection against contamination and moisture ingress. Crafted from premium materials and subjected to rigorous quality control measures, this bearing exemplifies the pinnacle of precision engineering.

|

2 Characteristics and Specifications of 6307-2RZ Bearing

Technical Specifications

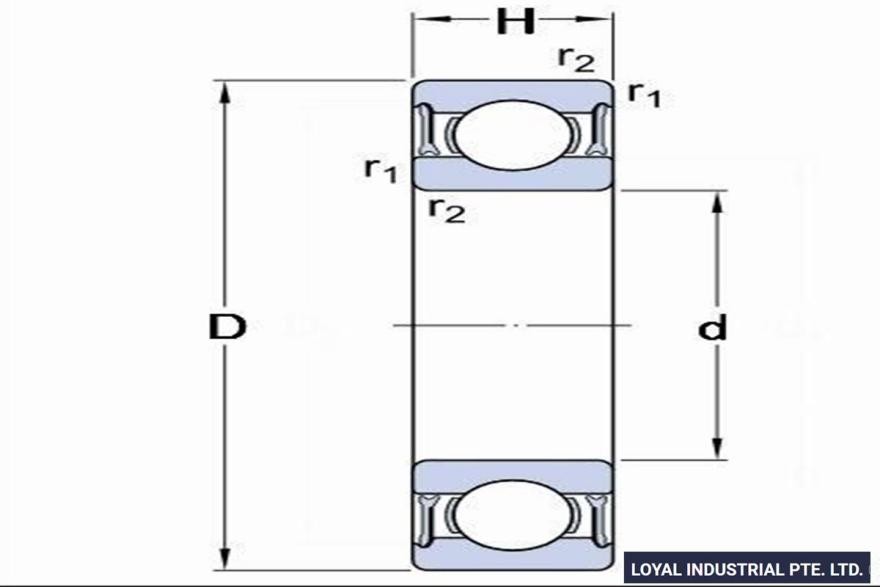

The 6307-2RZ bearing is distinguished by its precise dimensions and robust construction, making it suitable for a wide range of high-speed applications in European machinery. With a bore diameter of 35 mm, an outer diameter of 80 mm, and a width of 21 mm, this bearing offers optimal fit and compatibility with various shafts and housings. Furthermore, the bearing's speed ratings, including its maximum rotational speed and permissible operating temperatures, make it well-suited for use in dynamic environments where efficiency and durability are paramount.

Material Composition and Manufacturing Process

Crafted from premium-grade materials, the 6307-2RZ bearing undergoes a meticulous manufacturing process to ensure exceptional quality and precision. The inner and outer rings are typically constructed from high-grade steel, providing excellent strength and durability to withstand heavy loads and extreme operating conditions. Additionally, the rolling elements, commonly made of ceramic or stainless steel, exhibit superior hardness and corrosion resistance, contributing to the bearing's extended service life. Advanced machining techniques, such as precision grinding and heat treatment, further enhance the dimensional accuracy and surface finish of the bearing components, guaranteeing optimal performance and reliability.

Sealing Mechanisms and Benefits of RZ Design

One of the distinguishing features of the 6307-2RZ bearing is its innovative sealing mechanism, which provides superior protection against contamination and moisture ingress. The 2RZ designation signifies a non-contact seal on both sides of the bearing, effectively preventing the entry of foreign particles and lubricant leakage. This RZ design not only extends the bearing's service life by maintaining clean internal surfaces but also reduces frictional losses and energy consumption, thereby enhancing overall efficiency and performance. Moreover, the absence of frictional contact between the seal and the inner ring allows for smoother rotation and quieter operation, making the 6307-2RZ bearing ideal for noise-sensitive applications in European machinery.

Comparison with Other Bearing Types

In comparison to alternative bearing configurations, such as open or shielded designs, the 6307-2RZ bearing offers distinct advantages in terms of sealing effectiveness, contamination resistance, and operational reliability. While open bearings provide maximum accessibility for lubrication and maintenance, they are more susceptible to contamination and require frequent re-greasing. On the other hand, shielded bearings offer moderate protection against debris but may compromise sealing integrity at higher speeds or temperatures. In contrast, the 6307-2RZ bearing strikes a balance between accessibility and protection, combining the convenience of non-contact seals with the durability of high-quality materials to deliver unparalleled performance in European machinery applications.

Brands and Variants of 6307-2RZ Bearings

Below is a comparison table highlighting different brands and their variants of 6307-2RZ bearings, along with key differentiators:

|

Brand |

Key Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality steel construction |

- Excellent durability and longevity |

- Higher initial cost |

|

NSK |

- Advanced sealing technology |

- Superior resistance to contaminants |

- Slightly lower load capacity than competitors |

|

FAG |

- Precision engineering for optimal performance |

- Wide operating temperature range |

- May require more frequent maintenance |

|

NTN |

- Diverse range of applications compatibility |

- Cost-effective solution for various industries |

- May not offer the same level of precision |

|

Timken |

- Enhanced load capacity |

- Exceptional performance under heavy loads |

- Limited availability in certain regions |

|

Nachi |

- High-speed capabilities |

- Smooth operation even at elevated speeds |

- Less commonly used in certain industrial sectors |

|

Koyo |

- Robust design for harsh environments |

- Reliable performance in challenging conditions |

- Limited aftermarket support in some regions |

As we delve deeper into the characteristics and specifications of the 6307-2RZ bearing, it becomes evident that its advanced design and superior performance make it a preferred choice for discerning manufacturers seeking high-quality solutions for their machinery needs. From its precise dimensions to its innovative sealing mechanism, every aspect of this bearing is engineered to exceed expectations and elevate the standards of performance in European machinery applications.

3 Applications and Performance Analysis

The 6307-2RZ bearing exemplifies unparalleled precision and reliability, making it a cornerstone component in European machinery across various industries. Its versatile applications and exceptional performance characteristics contribute significantly to enhancing overall machinery efficiency and productivity.

Utilization of 6307-2RZ Bearing in European Machinery

|

Automotive Industry |

In the automotive sector, 6307-2RZ bearings are integral components in engine assemblies, supporting camshafts and ensuring precise timing of valve operations. These bearings also find their place in chassis systems, where they aid in steering linkages, providing stability and maneuverability. Additionally, transmission systems rely on 6307-2RZ bearings for smooth gear shifting and efficient power transmission.

|

|

Industrial Machinery |

Within industrial settings, 6307-2RZ bearings play crucial roles in conveyor systems, facilitating the movement of materials with minimal friction. They are also utilized in pump assemblies, where they contribute to reliable fluid handling and pressure regulation. Moreover, industrial fans and blowers benefit from the precision operation enabled by these bearings, ensuring optimal airflow and ventilation.

|

|

Agricultural Equipment |

In the agricultural sector, 6307-2RZ bearings are employed in tractor drivetrain components, including PTO shafts and transmission systems. Harvesting machinery, such as combine harvesters, relies on these bearings for efficient grain processing and crop harvesting. Additionally, irrigation systems utilize 6307-2RZ bearings in pivot points, ensuring precise movement and distribution of water resources.

|

|

Construction Machinery |

Construction equipment relies heavily on 6307-2RZ bearings for various applications. Excavators depend on these bearings for smooth operation of swing gears and hydraulic cylinders, enabling efficient digging and earthmoving tasks. Cranes utilize 6307-2RZ bearings in lifting mechanisms, ensuring safe and reliable lifting of heavy loads at construction sites.

|

|

Marine Systems |

In the marine industry, 6307-2RZ bearings are essential components of propulsion systems, supporting propeller shafts and ensuring efficient power delivery to marine vessels. Deck machinery, including winch systems, relies on these bearings for smooth operation during loading and unloading activities. Moreover, marine navigation equipment benefits from the precision performance of 6307-2RZ bearings in steering systems and thruster assemblies.

|

|

Renewable Energy Sector |

In the renewable energy sector, 6307-2RZ bearings play vital roles in wind turbine generators, supporting yaw bearings and ensuring precise alignment with wind direction for optimal energy capture. Solar tracking systems utilize these bearings to track the sun's movement, maximizing solar energy harvesting efficiency. Additionally, hydroelectric turbine systems rely on 6307-2RZ bearings for smooth operation of turbine shafts and sluice gates, enabling efficient energy generation from water resources.

|

In summary, the applications of 6307-2RZ bearings in European machinery span across a wide range of industries, showcasing their versatility, reliability, and importance in ensuring the smooth operation of mechanical systems across various sectors.

Case Studies Highlighting Performance in Various Industries

Numerous case studies underscore the exemplary performance of the 6307-2RZ bearing in real-world applications across diverse industries. For instance, in a manufacturing setting, a leading European machinery manufacturer reported a significant increase in equipment uptime and operational efficiency following the adoption of 6307-2RZ bearings in their production line. The bearings' superior durability and resistance to wear minimized the need for unscheduled maintenance, resulting in substantial cost savings and improved overall equipment effectiveness.

Endurance and Reliability Under Different Operating Conditions

The 6307-2RZ bearing demonstrates exceptional endurance and reliability under a myriad of operating conditions, ranging from high-speed rotation to heavy load-bearing scenarios. Its robust construction and advanced sealing mechanism provide unparalleled protection against contaminants, ensuring long-term performance stability even in the harshest industrial environments. Whether subjected to extreme temperatures, corrosive substances, or mechanical shocks, this bearing remains steadfast in its commitment to delivering consistent performance and uncompromising reliability.

Impact on Overall Machinery Efficiency and Productivity

The adoption of 6307-2RZ bearings in European machinery has a profound impact on overall equipment efficiency and productivity. By minimizing frictional losses, reducing maintenance downtime, and extending service intervals, these bearings contribute to optimizing machinery performance and maximizing throughput. Moreover, their compatibility with advanced predictive maintenance systems enables proactive monitoring of bearing health, further enhancing operational reliability and cost-effectiveness.

In summary, the 6307-2RZ bearing stands as a testament to the relentless pursuit of high-quality performance in European machinery. Its widespread applications, proven performance, and positive impact on machinery efficiency underscore its significance as a cornerstone component in modern industrial operations.

4 Maintenance and Care Practices

Proper maintenance of the 6307-2RZ bearing is essential to ensure its longevity and sustained high-quality performance in European machinery. Implementing recommended maintenance practices not only extends the service life of the bearing but also enhances overall machinery efficiency and productivity.

Importance of Proper Maintenance for Longevity

Maintaining the 6307-2RZ bearing in optimal condition is paramount to prevent premature failure and costly downtime. Regular maintenance routines, including lubrication, inspection, and cleaning, help mitigate wear and tear, prolonging the bearing's service life and preserving its precision performance. Neglecting maintenance can lead to increased friction, heat generation, and ultimately, bearing failure, jeopardizing the reliability and safety of machinery operations.

Recommended Lubrication Intervals and Techniques

Lubrication plays a crucial role in reducing friction and minimizing wear between bearing components. For the 6307-2RZ bearing, selecting the appropriate lubricant and adhering to recommended intervals is imperative to ensure smooth operation and prevent premature failure. European machinery manufacturers often recommend high-quality synthetic lubricants with additives specifically formulated to withstand high speeds and operating temperatures. Proper lubrication techniques, such as applying the correct amount of grease or oil and distributing it evenly across bearing surfaces, help optimize performance and extend service intervals.

Inspection Procedures to Detect Wear and Damage

Regular inspections are key to identifying potential issues with the 6307-2RZ bearing before they escalate into critical problems. Visual inspections, conducted at predetermined intervals, allow maintenance personnel to assess the condition of the bearing, looking for signs of wear, corrosion, or damage. Additionally, advanced techniques such as vibration analysis and thermography can provide insights into the bearing's health and detect abnormalities indicative of impending failure. Prompt identification of issues enables timely intervention, preventing costly repairs and unplanned downtime.

Troubleshooting Common Issues and Solutions

Despite meticulous maintenance, occasional issues may arise with the 6307-2RZ bearing due to operational factors or environmental conditions. Common issues such as overheating, abnormal noise, or reduced performance require swift troubleshooting to minimize disruption to machinery operations. European machinery manufacturers often provide comprehensive troubleshooting guides, outlining common symptoms, possible causes, and recommended solutions for addressing bearing-related problems. By following these guidelines and leveraging expertise from authorized service providers, maintenance teams can swiftly resolve issues and restore machinery to optimal working condition.

In conclusion, prioritizing maintenance and care practices is essential for maximizing the performance and longevity of the 6307-2RZ bearing in European machinery. By adhering to recommended maintenance intervals, lubrication techniques, inspection procedures, and troubleshooting protocols, manufacturers can ensure uninterrupted operation, minimize downtime, and uphold the highest standards of performance and reliability.

5 Conclusion

In conclusion, the 6307-2RZ bearing emerges as a cornerstone component in European machinery, epitomizing high-quality performance and precision engineering. Throughout this exploration, we have delved into the multifaceted aspects of this bearing, from its technical specifications and applications to its maintenance practices and significance in the industrial landscape.

Recap of the Significance of 6307-2RZ Bearing in European Machinery

The 6307-2RZ bearing plays a pivotal role in European machinery, serving as a linchpin for smooth and efficient operation across diverse industries. Its robust construction, advanced sealing mechanisms, and superior performance characteristics make it indispensable in applications where reliability, durability, and precision are non-negotiable.

Key Takeaways Regarding Performance, Applications, and Maintenance

Throughout our exploration, several key takeaways have emerged regarding the 6307-2RZ bearing. From its ability to withstand high speeds and heavy loads to its versatility across various industries, this bearing exemplifies excellence in performance and adaptability. Moreover, adherence to recommended maintenance practices ensures its longevity and sustained performance, safeguarding machinery uptime and productivity.

Closing Remarks on the Role of High-Quality Bearings in Ensuring Optimal Machinery Operation

As we conclude our discussion, it becomes evident that high-quality bearings, such as the 6307-2RZ, are the cornerstone of optimal machinery operation. By investing in precision-engineered components like the 6307-2RZ bearing, European machinery manufacturers uphold their commitment to excellence, innovation, and reliability. These bearings not only elevate the performance standards of machinery but also contribute to the overall competitiveness and success of industries across the continent.

In essence, the 6307-2RZ bearing symbolizes the epitome of high-quality performance in European machinery, embodying the ethos of precision engineering, reliability, and innovation. As technology advances and industries evolve, the role of such bearings will continue to be paramount in driving efficiency, productivity, and success in the ever-changing landscape of European manufacturing.

6 FAQs: Common Questions About 6307-2RZ Bearing

Q1: What distinguishes the 6307-2RZ bearing from other bearing types?

The 6307-2RZ bearing stands out from other bearing types due to its high-speed, deep groove ball design tailored for precision motor applications. Its advanced RZ sealing technology ensures superior protection against contamination and moisture ingress, setting it apart in terms of reliability and longevity.

Q2: In which industries is the 6307-2RZ bearing commonly utilized?

The 6307-2RZ bearing finds extensive use across various industries, including automotive, aerospace, manufacturing, and renewable energy. Its versatility and reliability make it indispensable in applications requiring precision and durability.

Q3: How should the 6307-2RZ bearing be maintained for optimal performance?

To maintain optimal performance, regular lubrication with high-quality synthetic lubricants is essential for the 6307-2RZ bearing. Adhering to recommended maintenance intervals and conducting thorough inspections for wear and damage are also crucial practices.

Q4: How does the 6307-2RZ bearing contribute to the efficiency of high-speed machinery?

The precision engineering of the 6307-2RZ bearing facilitates smooth and efficient operation at high speeds, thereby optimizing the performance of European machinery. Its deep groove design enables it to accommodate radial and axial loads with ease, while the RZ seals provide superior protection against dust and moisture ingress, maintaining consistent performance levels even in challenging operating conditions.

Q5: What are the benefits of using the 6307-2RZ bearing in European machinery?

Using the 6307-2RZ bearing in European machinery offers numerous benefits, including exceptional precision, reliability, and durability. Its ability to withstand high speeds, heavy loads, and harsh operating conditions contributes to enhanced machinery efficiency and productivity.

As these FAQs demonstrate, the 6307-2RZ bearing is a cornerstone component in European machinery, offering unmatched performance and reliability across diverse applications. Its advanced design and precision engineering make it an indispensable asset for manufacturers striving for high-quality performance in their machinery.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings