Home> Bearing Technology> Ensuring Longevity and Performance: 6206RS Sealed Ball Bearings in European Applications

Ensuring Longevity and Performance: 6206RS Sealed Ball Bearings in European Applications

NOVEMBER 02, 20221 Introduction

Definition and Features of 6206RS Bearings:

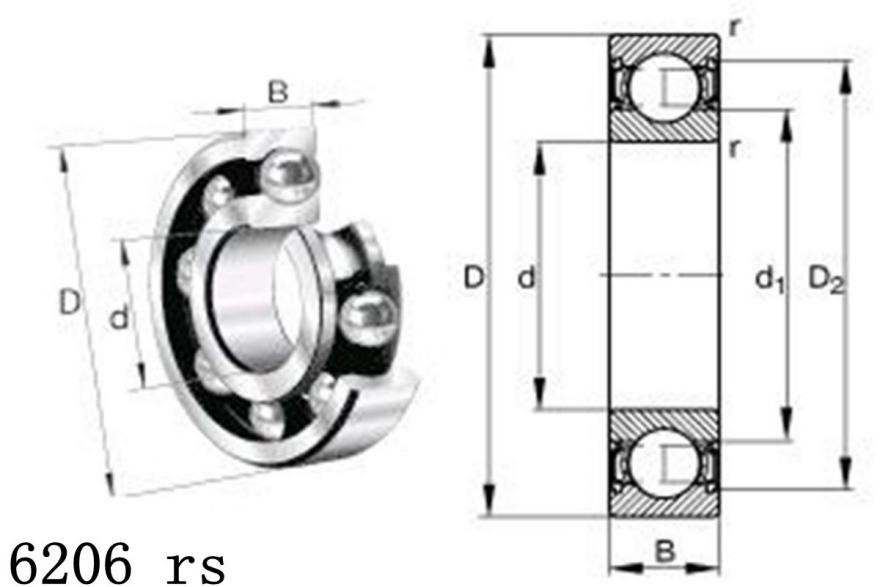

6206RS sealed ball bearings are precision-engineered components designed to provide optimal performance and longevity in various industrial applications. These bearings feature a sealed design, which effectively prevents contaminants such as dust, dirt, and moisture from entering the bearing, thus ensuring smooth operation and prolonged lifespan. The "6206" designation refers to the bearing's specific size and dimensions, while "RS" denotes the sealing mechanism used, typically a rubber seal.

Importance of Longevity and Performance in European Applications:

In European industries, where precision engineering and reliability are paramount, the importance of longevity and performance cannot be overstated. Machinery and equipment in sectors such as automotive manufacturing, aerospace, and robotics require components that can withstand rigorous operating conditions while delivering consistent performance over time. 6206RS sealed ball bearings play a crucial role in ensuring the reliability and efficiency of these systems, thereby contributing to the overall productivity and competitiveness of European industries.

Overview of European Industrial Landscape:

The European industrial landscape encompasses a diverse range of sectors, including automotive, aerospace, manufacturing, and automation. These industries are characterized by their commitment to innovation, quality, and sustainability. As Europe continues to lead in technological advancements and precision engineering, the demand for high-quality components such as 6206RS sealed ball bearings remains strong. Understanding the unique requirements and challenges of European applications is essential for maximizing the benefits of these bearings and driving continued success in the region's industrial sectors.

The following is an introduction to the 6206 rs bearing brand

|

Brand |

Description |

Features |

Benefits |

|

SKF |

SKF 6206RS bearings are known for their high quality and reliability. They are precision-engineered to withstand heavy loads and harsh operating conditions. |

SKF 6206RS bearings are precision-engineered with high-quality steel and advanced sealing technology. |

They offer exceptional durability, high load capacity, and resistance to contamination, making them ideal for various industrial applications. |

|

NSK |

NSK 6206RS bearings are renowned for their precision and performance. They are designed for smooth operation and long service life. |

NSK 6206RS bearings feature precision-ground raceways, optimized internal geometry, and advanced sealing systems. |

They provide smooth and quiet operation, extended service life, and reduced maintenance requirements, ensuring reliable performance in demanding environments. |

|

FAG |

FAG 6206RS bearings are known for their superior performance and reliability in demanding applications. They are engineered to deliver consistent performance under varying conditions. |

FAG 6206RS bearings boast a robust cage design, enhanced sealing properties, and lubrication optimization. |

With high-speed capability, excellent resistance to contamination, and minimal friction and heat generation, FAG bearings deliver consistent performance in various applications. |

|

NTN |

NTN 6206RS bearings are designed for maximum efficiency and durability. They feature advanced materials and manufacturing techniques to ensure reliable performance. |

NTN 6206RS bearings are constructed with premium-grade steel, precision machining, and multi-lip seals. |

They provide enhanced wear resistance, reduced friction and heat generation, and extended service intervals, ensuring reliable operation in challenging conditions. |

|

Timken |

Timken 6206RS bearings are engineered for optimal performance and longevity. They are built to withstand heavy loads and extreme conditions. |

Timken 6206RS bearings feature high-grade steel construction, advanced sealing technology, and an enhanced lubrication system. |

Offering exceptional load capacity, resistance to wear and tear, and extended service life, Timken bearings are preferred for demanding industrial applications. |

Each of these brands has earned a reputation for excellence in bearing technology, offering products that meet the stringent requirements of modern industrial applications. Whether it's SKF's reliability, NSK's precision, FAG's performance, NTN's durability, or Timken's engineering expertise, customers can trust these brands to deliver superior-quality 6206RS bearings for their machinery and equipment needs.

2 Advantages of 6206RS Sealed Ball Bearings

|

Enhanced Durability and Resistance to Wear |

6206RS sealed ball bearings are renowned for their exceptional durability and resistance to wear, making them ideal for demanding industrial applications in European industries. The sealed design effectively protects the bearings from contaminants such as dust, dirt, and moisture, significantly extending their service life. This enhanced durability ensures consistent performance over time, reducing the need for frequent replacements and maintenance interventions. |

|

Contribution to Energy Efficiency and Cost Savings |

In European applications, where energy efficiency is a priority, 6206RS sealed ball bearings play a crucial role in reducing energy consumption and operating costs. By minimizing friction and optimizing motion control, these bearings contribute to improved energy efficiency in machinery and equipment. The reduction in energy consumption not only lowers operational expenses but also aligns with sustainability goals, making 6206RS bearings a preferred choice for environmentally-conscious industries. |

|

Impact on Overall Machinery Performance in European Industries |

The adoption of 6206RS sealed ball bearings has a significant impact on the overall performance of machinery in European industries. These bearings ensure smooth operation, precise motion control, and reliable performance under varying operating conditions. Whether in automotive manufacturing, aerospace applications, or industrial automation, 6206RS bearings contribute to enhanced productivity, efficiency, and quality of output. Their ability to withstand rigorous industrial environments while maintaining optimal performance makes them indispensable components in European machinery and equipment. |

In summary, the advantages of 6206RS sealed ball bearings, including enhanced durability, energy efficiency, and improved machinery performance, make them indispensable components in European applications. Their ability to ensure longevity and performance in demanding industrial environments underscores their importance in driving operational excellence and competitiveness across various sectors.

3 Case Studies: Applications in European Industries

|

Automotive Sector |

Utilization of 6206RS Bearings in European Car Manufacturing

|

|

Aerospace Industry |

Integration of 6206RS Bearings in European Aircraft Systems

|

|

Manufacturing and Robotics |

Adoption of 6206RS Bearings in European Industrial Automation In the realm of manufacturing and robotics, European industries rely on advanced automation systems to streamline production processes and improve efficiency. 6206RS sealed ball bearings play a crucial role in these systems, providing reliable motion control and precision positioning in industrial robots and automated machinery. By adopting 6206RS bearings, European manufacturers can achieve higher productivity, reduced downtime, and improved quality control in their operations, leading to greater competitiveness in the global market.

|

These case studies highlight the diverse applications of 6206RS sealed ball bearings in European industries, demonstrating their versatility, reliability, and performance across automotive manufacturing, aerospace engineering, and industrial automation. By integrating 6206RS bearings into their systems and machinery, European companies can ensure longevity and performance, driving innovation and excellence in their respective fields.

4. Challenges and Solutions

Addressing Specific Challenges Faced by European Industries:

European industries encounter various challenges related to machinery and equipment, where the performance of components such as bearings can significantly impact overall efficiency. One of the primary challenges is ensuring the longevity and reliability of machinery in demanding operating conditions. Factors such as high temperatures, heavy loads, and exposure to contaminants pose threats to the performance of bearings. In addressing these challenges, European industries rely on advanced solutions, including the adoption of 6206RS sealed ball bearings.

Innovative Solutions and Technological Advancements in 6206RS Bearings:

To meet the evolving needs of European industries, manufacturers of 6206RS sealed ball bearings continually innovate and develop advanced technologies. These innovations aim to enhance the durability, performance, and efficiency of bearings, thereby addressing the specific challenges faced by European industries. For instance, advancements in sealing technologies improve the protection of bearings against contaminants, while advancements in materials and lubrication techniques enhance their durability and reliability.

Collaborative Efforts for Continuous Improvement:

European industries recognize the importance of collaboration and knowledge-sharing in overcoming challenges and driving continuous improvement. Manufacturers, suppliers, and industry experts collaborate to exchange insights, best practices, and innovative solutions related to bearing technology. Through collaborative efforts, European industries can harness the collective expertise and resources available to address challenges effectively and ensure the optimal performance of machinery and equipment.

By addressing specific challenges, leveraging innovative solutions, and fostering collaborative efforts, European industries can overcome obstacles related to machinery performance and ensure the longevity and performance of 6206RS sealed ball bearings in various applications.

In conclusion, European industries face challenges related to machinery performance, but through innovative solutions and collaborative efforts, they can overcome these obstacles. The utilization of advanced technologies, such as 6206RS sealed ball bearings, plays a crucial role in addressing these challenges and ensuring longevity and performance in European applications.

5. Future Prospects and Opportunities

Emerging Trends in European Engineering and Manufacturing:

European engineering and manufacturing industries are witnessing a shift towards automation, digitization, and sustainability. As technology continues to evolve, new trends such as Industry 4.0, Internet of Things (IoT), and additive manufacturing are reshaping the landscape. These trends present opportunities for enhancing efficiency, productivity, and sustainability in European applications, driving the demand for advanced components like 6206RS sealed ball bearings.

Potential Developments in Bearing Technology for European Applications:

The future of bearing technology holds promising advancements aimed at addressing the evolving needs of European industries. Manufacturers are investing in research and development to improve bearing materials, designs, and manufacturing processes. Nanotechnology, advanced coatings, and predictive maintenance techniques are expected to play significant roles in enhancing the performance and longevity of bearings in European applications. These developments will further solidify the position of 6206RS sealed ball bearings as indispensable components in European machinery and equipment.

Strategies for Harnessing the Full Potential of 6206RS Sealed Ball Bearings:

To capitalize on the opportunities presented by emerging trends and advancements in bearing technology, European industries must adopt strategic approaches. This includes prioritizing investments in research and development, fostering collaborations between industry stakeholders and academia, and embracing innovative manufacturing processes. By leveraging the full potential of 6206RS sealed ball bearings and integrating them into future-ready systems, European industries can stay ahead of the curve and maintain their competitive edge in the global market.

In summary, the future prospects and opportunities for 6206RS sealed ball bearings in European applications are promising. By aligning with emerging trends, embracing technological advancements, and implementing strategic initiatives, European industries can maximize the benefits of these bearings and drive innovation and growth in their respective sectors.

The future of 6206RS sealed ball bearings in European applications is bright, with emerging trends and advancements in technology presenting new opportunities for innovation and growth. By staying abreast of these developments and implementing strategic initiatives, European industries can ensure the longevity and performance of their machinery while maintaining their competitiveness in the global market.

6. Conclusion

Summary of Key Findings and Insights:

Through the exploration of the role of 6206RS sealed ball bearings in European applications, it is evident that these components play a crucial role in ensuring the longevity and performance of machinery and equipment. By providing enhanced durability, resistance to wear, and contributing to energy efficiency, 6206RS bearings offer significant advantages over conventional bearings in various industrial sectors across Europe.

Outlook on the Role of 6206RS Bearings in Ensuring Longevity and Performance in European Applications:

Looking ahead, the outlook for 6206RS sealed ball bearings remains promising. As European industries continue to prioritize efficiency, productivity, and sustainability, the demand for high-performance components like 6206RS bearings is expected to grow. Manufacturers are likely to invest further in research and development to innovate and enhance bearing technologies, meeting the evolving needs of European applications.

Final Thoughts on the Significance of Precision Engineering in European Industries:

In conclusion, precision engineering, exemplified by the advancements in 6206RS sealed ball bearings, holds immense significance for European industries. These components serve as the foundation for efficient and reliable machinery, enabling industries to achieve their operational objectives while remaining competitive in the global market. As European industries navigate towards a future driven by innovation and sustainability, precision engineering, and advanced components like 6206RS bearings will continue to play pivotal roles in shaping their success.

In summary, the utilization of 6206RS sealed ball bearings in European applications underscores the importance of precision engineering in ensuring longevity and performance. With continuous advancements and strategic investments, these bearings will remain indispensable components in European industries, contributing to their growth, competitiveness, and sustainability.

7 FAQs: Common Questions About 6206 RS Bearing

1. What is a 6206 RS bearing?

A 6206 RS bearing is a type of deep groove ball bearing with a single rubber seal on one side (RS stands for rubber seal). It is commonly used in various industrial applications to support rotating shafts and reduce friction.

2. What are the advantages of using 6206 RS bearings?

6206 RS bearings offer several advantages, including enhanced durability, resistance to contamination and moisture, reduced noise and vibration levels, and improved sealing effectiveness. These features make them ideal for demanding applications where reliability and performance are critical.

3. How does a 6206 RS bearing contribute to longevity and performance in European applications?

In European applications, 6206 RS bearings play a vital role in ensuring the longevity and performance of machinery and equipment. By providing reliable sealing, smooth operation, and resistance to harsh operating conditions, these bearings help extend the service life of components and minimize downtime, thereby enhancing overall efficiency and productivity.

4. Are 6206 RS bearings suitable for high-speed applications?

Yes, 6206 RS bearings are suitable for moderate to high-speed applications, depending on factors such as lubrication, load, and operating temperature. Proper maintenance and lubrication are essential to maximize the performance and longevity of these bearings in high-speed applications.

5. How can I identify a genuine 6206 RS bearing?

Genuine 6206 RS bearings typically feature specific markings, such as the manufacturer's logo, part number, and country of origin. Additionally, they undergo rigorous quality control processes to ensure consistency and reliability. It is essential to purchase bearings from reputable suppliers to guarantee authenticity and performance.

In summary, the FAQs provide valuable insights into the characteristics, benefits, and applications of 6206 RS sealed ball bearings, highlighting their importance in ensuring longevity and performance in European applications.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings