Home> Bearing Technology> Magnetic Bearing Origins: Exploring Utility and Innovative Adaptations

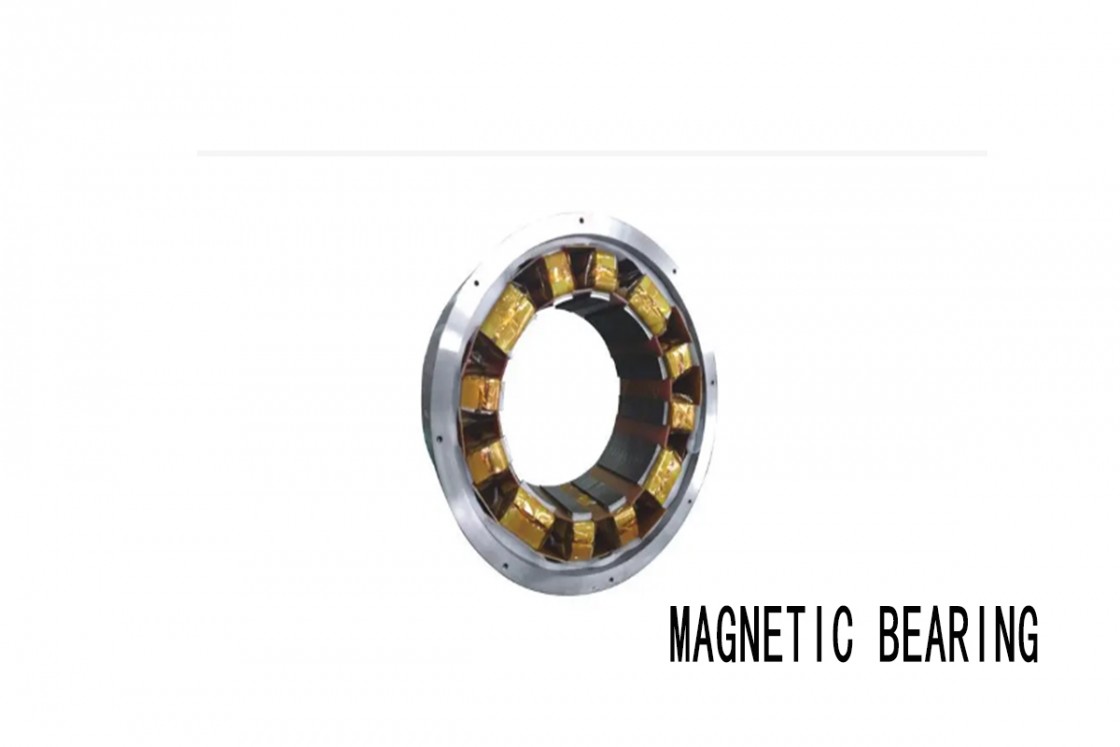

Introduction to Magnetic Bearings

Magnetic bearings represent a significant advancement in bearing technology, utilizing magnetic forces to support and stabilize rotating shafts without direct contact. This innovative design minimizes friction and wear, making magnetic bearings an essential component in various high-performance applications.

Definition and Basic Principles of Magnetic Bearings

A magnetic bearing is a type of bearing that uses magnetic fields to levitate and support a rotor or shaft. Unlike traditional bearings that rely on physical contact between surfaces, magnetic bearings function based on the principles of electromagnetism. By employing either permanent magnets or electromagnets, these bearings create a magnetic field that holds the rotor in place, allowing it to spin freely without contact.

Key principles include:

Levitation: Magnetic forces counteract gravitational and operational loads, allowing the rotor to float within a predetermined space. This levitation reduces friction to virtually zero, leading to increased efficiency.

Active Control: Most magnetic bearing systems incorporate active control mechanisms that continuously adjust the magnetic field in response to changes in load, speed, and position. This dynamic adjustment ensures stability and precision during operation.

Non-contact Operation: The absence of physical contact between the bearing surfaces results in significantly reduced wear and tear, extending the lifespan of both the bearing and the supported machinery.

Overview of Their Role in Modern Engineering and Technology

Magnetic bearings are increasingly pivotal in modern engineering, impacting a variety of sectors, including:

Aerospace: In aircraft engines and satellite systems, magnetic bearings ensure reliable performance under extreme conditions while minimizing maintenance needs.

Industrial Machinery: Many manufacturing processes utilize magnetic bearings in turbines, compressors, and pumps, where efficiency and reliability are paramount.

Electric Motors: Electric and hybrid vehicles are beginning to adopt magnetic bearings for their motors, leading to quieter operation and increased efficiency.

Medical Devices: In sensitive medical applications, such as MRI machines, magnetic bearings contribute to precision and reliability, crucial for patient safety and accurate diagnostics.

In summary, magnetic bearings serve as a cornerstone of modern engineering solutions, providing innovative adaptations across numerous industries. Their unique properties of frictionless operation and active control mechanisms make them indispensable for achieving higher performance standards and advancing technology.

Historical Origins of Magnetic Bearings

Magnetic bearings represent a groundbreaking advancement in engineering, offering a frictionless alternative to traditional bearings. Their development has roots that trace back to early explorations of magnetism and electromagnetism, leading to significant innovations in various industries.

Early Developments and Pioneers in Magnetic Bearing Technology

The concept of using magnetic forces to support rotating shafts can be traced back to the mid-20th century. One of the earliest pioneers was H. G. Stiefel, who conducted foundational research on the potential of magnetic levitation. His work laid the groundwork for further exploration into how magnetic fields could be utilized to create non-contact support systems.

In the 1970s, the field gained momentum with contributions from engineers and researchers like , who developed theoretical models that demonstrated the feasibility of using magnetic fields to stabilize moving parts. The collaboration between academia and industry led to the gradual emergence of prototypes that would eventually lead to practical applications.

Evolution from Concept to Practical Application

The transition from theoretical concepts to real-world applications of magnetic bearings saw significant advancements during the 1980s and 1990s. Notably, the advent of high-temperature superconductors revolutionized the field, enabling the creation of more efficient and powerful magnetic bearings. This technological leap not only improved performance but also broadened the scope of applications.

Magnetic bearings found their initial use in industries requiring high precision and reliability, such as aerospace and power generation. For example, they became critical components in turbomachinery, where the need for minimal friction and wear was paramount. As a result, the implementation of magnetic bearings led to enhanced operational efficiency and reduced maintenance costs.

Moreover, the growth of computer technology during this period played a crucial role in the development of advanced control systems for magnetic bearings. These systems allowed for real-time adjustments and monitoring, further improving the stability and performance of magnetic bearing applications.

Overall, the historical journey of magnetic bearings showcases a fascinating evolution marked by innovation and practical adaptation, establishing them as essential components in modern engineering applications.

Utility of Magnetic Bearings in Various Applications

Magnetic bearings represent a significant advancement in the field of mechanical engineering, providing unique benefits that make them increasingly popular across various industries. This section will explore the utility of magnetic bearings, highlighting their advantages over traditional bearings, and identifying the key industries that have embraced this innovative technology.

Advantages Over Traditional Bearings

One of the primary advantages of magnetic bearings is their ability to reduce friction. Unlike conventional bearings, which rely on physical contact between moving parts, magnetic bearings utilize magnetic fields to support the load, resulting in nearly frictionless operation. This reduction in friction leads to several benefits:

|

Adva ntages of Magnetic Bearings |

Description |

|

Maintenance-Free Operation |

Due to the absence of physical contact, magnetic bearings experience minimal wear and tear, reducing the need for regular maintenance and increasing operational efficiency. |

|

Higher Efficiency |

The frictionless nature of magnetic bearings allows for higher speeds and improved efficiency, particularly beneficial in high-speed rotating equipment. |

|

Temperature Stability |

With less friction, there is less heat generation. Magnetic bearings maintain better thermal stability, crucial for reliable operation in high-performance environments. |

|

Vibration Damping |

The active control systems in magnetic bearings effectively dampen vibrations, contributing to smoother operation and reduced noise levels in sensitive applications. |

Key Industries Utilizing Magnetic Bearings

The versatility of magnetic bearings has led to their adoption in several key industries, each harnessing their unique advantages for specific applications:

Aerospace: In aerospace applications, magnetic bearings are crucial for reducing weight and enhancing reliability. They are often used in turbine engines and other critical systems, where failure is not an option. The aerospace industry benefits from the high performance and durability of magnetic bearings, ensuring safe and efficient flight operations.

Industrial Machinery: Many industrial processes rely on magnetic bearings to improve productivity and reduce downtime. In machines like compressors and turbines, these bearings enable smoother operation, thus enhancing overall machinery lifespan and performance.

Energy Sector: In renewable energy applications, such as wind turbines and generators, magnetic bearings play a vital role in maintaining operational efficiency. Their ability to operate without lubrication makes them ideal for remote locations, where maintenance access is limited.

Semiconductor Manufacturing: The semiconductor industry requires extreme precision and cleanliness. Magnetic bearings support equipment used in this sector by ensuring minimal contamination and high-speed operation, crucial for producing microelectronics.

Conclusion

The utility of magnetic bearings extends far beyond mere functionality; they are a transformative technology reshaping various industries. By offering reduced friction, maintenance-free operation, and superior performance, magnetic bearings are paving the way for innovations in aerospace, industrial machinery, energy, and semiconductor manufacturing. As these industries continue to evolve, the demand for efficient and reliable solutions like magnetic bearings will undoubtedly increase, leading to further advancements and applications in the future.

Innovative Adaptations in Magnetic Bearing Design

Magnetic bearings have evolved significantly over the years, thanks to continuous research and development. explores the innovative adaptations in the design of magnetic bearings, focusing on advances in materials and unique design features that enhance their performance and efficiency.

Advances in Materials Used

The performance of magnetic bearings heavily depends on the materials utilized in their construction. Recent innovations have introduced advanced materials that improve the functionality and durability of these bearings:

Superconductors: Superconducting materials are at the forefront of magnetic bearing technology. These materials exhibit zero electrical resistance and can create strong magnetic fields with minimal energy consumption. The incorporation of superconductors allows for high-performance applications where efficiency is paramount, such as in magnetic levitation systems.

Magnetic Alloys: The development of specialized magnetic alloys has also played a crucial role in enhancing the capabilities of magnetic bearings. These alloys are engineered to provide optimal magnetic properties, improving load capacity and reducing energy loss. Their strength and resilience make them ideal for high-stress environments, ensuring longevity and reliability.

Composite Materials: The use of composite materials combines the benefits of different substances to create lightweight yet strong components. In magnetic bearings, composites can help reduce weight while maintaining structural integrity, making them suitable for aerospace and other weight-sensitive applications.

Unique Design Features Enhancing Performance and Efficiency

The design of magnetic bearings incorporates several innovative features aimed at maximizing their efficiency and operational effectiveness:

|

nique Design Features of Magnetic Bearings |

Description |

|

Active Control Systems |

Modern magnetic bearings utilize advanced systems that dynamically adjust magnetic fields, enhancing stability and precision for high-speed applications. |

|

Self-Sensing Capabilities |

Many contemporary magnetic bearings feature self-sensing technology, enabling real-time performance monitoring and predictive maintenance. |

|

Modular Designs |

The modularity trend allows for easier customization and scalability, enabling quick upgrades without overhauling the entire system. |

|

Integrated Cooling Systems |

Innovative designs often include cooling systems to maintain optimal temperatures, preventing overheating and ensuring consistent performance. |

Conclusion

The continuous innovations in the design and materials used for magnetic bearings highlight their adaptability and potential for growth in various applications. By leveraging advanced materials such as superconductors and magnetic alloys, alongside unique design features that enhance efficiency and performance, magnetic bearings are set to play a pivotal role in the future of engineering and technology. As industries demand more reliable and efficient solutions, the evolution of magnetic bearing technology will undoubtedly keep pace with these needs.

Case Studies of Magnetic Bearing Implementations

The adoption of magnetic bearings across various industries demonstrates their transformative impact on performance and efficiency. This section presents several case studies showcasing successful implementations of magnetic bearings in real-world scenarios, highlighting the benefits and outcomes achieved through their integration.

Examples of Successful Applications

Aerospace Industry: Aircraft Engines

In the aerospace sector, magnetic bearings are increasingly used in aircraft engines. For instance, a leading aircraft manufacturer incorporated magnetic bearings in its turbofan engines. This integration reduced friction and wear, leading to a significant decrease in maintenance costs and an increase in operational reliability. The frictionless operation of magnetic bearings enabled the engines to achieve higher efficiency and extended service intervals.

Industrial Machinery: Turboexpanders

A prominent energy company utilized magnetic bearings in its turboexpanders, which are critical for natural gas processing. By employing magnetic bearings, the company achieved a reduction in energy consumption by over 20%. The ability of magnetic bearings to operate without lubrication minimized downtime and maintenance needs, resulting in a more reliable and cost-effective solution.

Renewable Energy: Wind Turbines

In the renewable energy sector, magnetic bearings are being used in wind turbines. One notable case involved the installation of magnetic bearings in a large wind turbine generator. This adaptation allowed for smoother operation and reduced vibration, which ultimately extended the lifespan of the turbine. Additionally, the reduced maintenance requirements translated to lower operational costs and improved energy production efficiency.

Semiconductor Manufacturing: Wafer Processing

Magnetic bearings are essential in the semiconductor manufacturing industry, particularly in wafer processing equipment. A leading semiconductor company integrated magnetic bearings in its lithography systems. This implementation resulted in enhanced precision and cleanliness, critical for producing high-quality microelectronics. The clean, lubrication-free operation of magnetic bearings significantly reduced contamination risks in the manufacturing process.

Benefits and Outcomes Achieved

The implementation of magnetic bearings across these case studies yielded several key benefits:

Reduced Maintenance Costs: In all scenarios, the transition to magnetic bearings led to a notable reduction in maintenance costs. The maintenance-free operation of these bearings minimizes the need for frequent servicing, allowing organizations to allocate resources more efficiently.

Increased Efficiency: The frictionless design of magnetic bearings resulted in significant improvements in overall system efficiency. This was particularly evident in high-speed applications, where traditional bearings often face limitations.

Enhanced Reliability: With fewer moving parts subject to wear, magnetic bearings provided greater reliability in critical applications. This reliability translates to improved operational uptime and reduced risk of failures.

Sustainability: The adoption of magnetic bearings contributes to sustainability efforts. By improving energy efficiency and reducing maintenance requirements, companies can operate more sustainably, aligning with modern environmental goals.

Conclusion

These case studies illustrate the profound impact of magnetic bearings in various industries, showcasing their successful implementation and the tangible benefits realized. As companies continue to seek innovative solutions to enhance efficiency and reliability, the role of magnetic bearings will undoubtedly expand, leading to even more groundbreaking applications in the future.

Future Trends and Developments

As the field of magnetic bearing technology continues to evolve, several emerging trends and developments indicate a promising future for this innovative solution. This section explores the latest advancements in research and technology related to magnetic bearings and provides predictions for their future trajectory.

Emerging Technologies and Research in Magnetic Bearing Innovation

Advancements in Smart Materials

Research into smart materials is significantly influencing the design of magnetic bearings. These materials can change their properties in response to environmental conditions, enhancing the adaptability and efficiency of magnetic bearings. For example, the integration of piezoelectric materials allows for real-time adjustments in magnetic fields, leading to more responsive and efficient systems.

Artificial Intelligence and Machine Learning

The incorporation of artificial intelligence (AI) and machine learning is set to revolutionize the operational capabilities of magnetic bearings. By utilizing AI algorithms, these systems can predict wear and performance issues, enabling proactive maintenance and optimization of operational parameters. This advancement not only increases reliability but also extends the lifespan of magnetic bearings.

Integration with IoT (Internet of Things)

The rise of IoT technologies is facilitating the connectivity of magnetic bearings with broader industrial systems. Smart sensors embedded within magnetic bearings can collect data and communicate with centralized systems, allowing for enhanced monitoring and control. This integration leads to better insights into performance and can optimize operational efficiency.

Hybrid Magnetic Bearings

Research is also focused on developing hybrid magnetic bearings, which combine traditional bearing technologies with magnetic bearing principles. This hybrid approach can offer a balance between cost-effectiveness and performance, making magnetic bearings accessible for a wider range of applications.

Predictions for the Future of Magnetic Bearing Technology

|

Future Trends in Magnetic Bearings |

Description |

|

Increased Adoption in Mainstream Applications |

As technology advances, magnetic bearings are expected to be adopted more broadly in industries like automotive and manufacturing, moving beyond specialized uses. |

|

Sustainability Focus |

The emphasis on sustainability will drive the development of more efficient magnetic bearings, prioritizing eco-friendly materials and energy-efficient designs. |

|

Customization and Flexibility |

Future magnetic bearings will be increasingly customizable, enabling manufacturers to tailor solutions to specific operational needs, thus enhancing efficiency. |

|

Enhanced Performance Metrics |

Advancements in monitoring technologies will provide deeper insights into operational conditions, allowing companies to achieve higher levels of performance and efficiency. |

Conclusion

The future of magnetic bearing technology is bright, marked by innovative research and the emergence of new technologies. As industries increasingly seek reliable, efficient, and sustainable solutions, magnetic bearings are poised to play a pivotal role in shaping the future of engineering and technology. With continued advancements in materials, AI integration, and IoT connectivity, the next generation of magnetic bearings promises to deliver exceptional performance and transformative benefits across multiple sectors.

Conclusion

In this comprehensive exploration of magnetic bearings, we have traced their evolution from early concepts to advanced implementations in various industries. The journey of magnetic bearing technology showcases a remarkable transformation that highlights its significant role in modern engineering.

Summary of the Evolution and Current State of Magnetic Bearings

Magnetic bearings have come a long way since their inception. Initially developed as an experimental solution to overcome the limitations of traditional bearings, they have now matured into reliable components widely used in high-performance applications. The evolution of magnetic bearing technology is marked by significant advancements in materials, control systems, and design features, enabling them to meet the rigorous demands of industries such as aerospace, automotive, and renewable energy.

Today, magnetic bearings are recognized for their frictionless operation, which leads to reduced maintenance costs, increased efficiency, and enhanced operational stability. The integration of smart technologies, including IoT and AI, has further elevated their functionality, allowing for real-time monitoring and predictive maintenance. As a result, the current state of magnetic bearings reflects a sophisticated understanding of both their capabilities and the challenges they face.

Insights into Their Ongoing Significance and Potential for Further Advancements

The ongoing significance of magnetic bearings lies in their ability to address modern engineering challenges, particularly in areas where precision and reliability are paramount. As industries increasingly prioritize sustainability, the energy-efficient nature of magnetic bearings positions them as a crucial component in the transition towards greener technologies. Furthermore, their potential for customization and adaptability opens new avenues for innovation across various sectors.

Looking ahead, the future of magnetic bearings is bright, with promising developments on the horizon. Emerging technologies, such as advanced materials and machine learning, will likely continue to enhance their performance and expand their applications. As research progresses, we can expect to see magnetic bearings integrated into even more diverse fields, from medical devices to advanced manufacturing systems.

Final Thoughts

In summary, magnetic bearings represent a pivotal advancement in bearing technology, combining innovation with practicality. Their journey reflects not only the evolution of engineering practices but also the potential for continued growth and adaptation in an ever-changing technological landscape. As we look to the future, the enduring relevance of magnetic bearings will undoubtedly shape the next generation of engineering solutions.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings