Home> Bearing Technology> Bush Bearing Showdown: THK vs. NMB vs. FAG – Comparing Performance and Reliability

Introduction

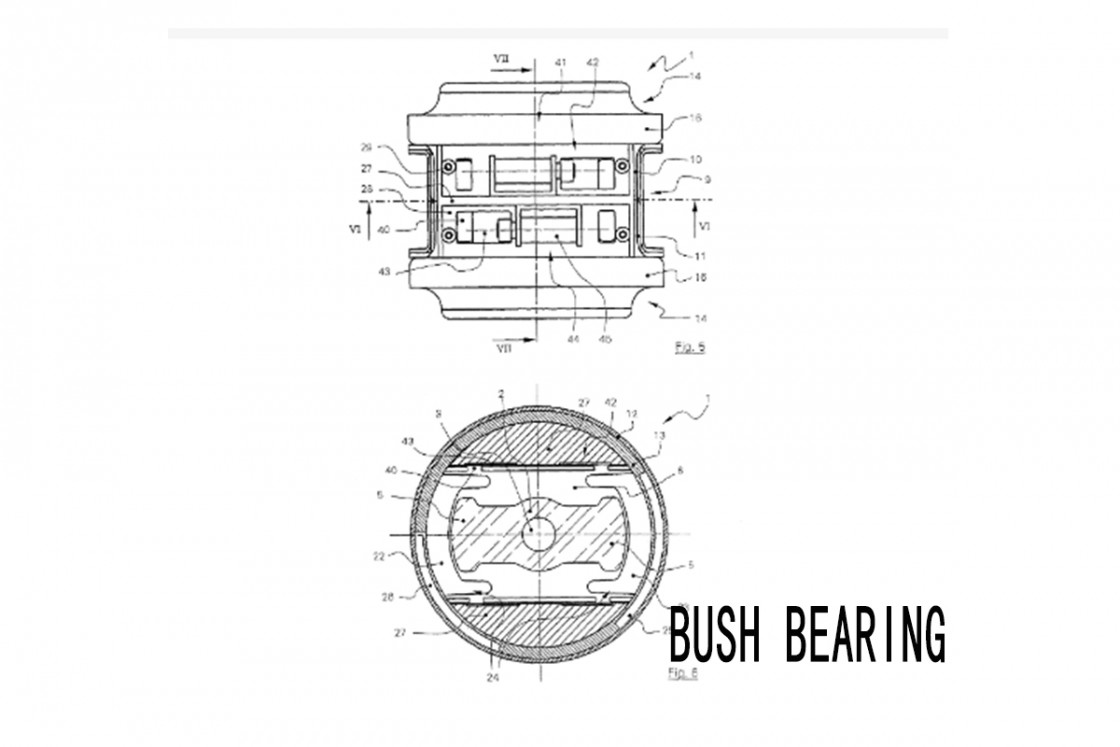

Overview of Bush Bearings and Their Significance

Bush bearings are essential components in various mechanical systems, known for their simplicity, reliability, and effectiveness in reducing friction between moving parts. These bearings consist of a cylindrical sleeve placed between rotating parts, often made from materials like bronze, graphite, or composite polymers. The primary function of a bush bearing is to support a rotating shaft and provide a low-friction interface, enhancing the longevity and efficiency of machinery.

In numerous applications, ranging from automotive and industrial machinery to household appliances, bush bearings are critical for ensuring smooth operation and reducing wear and tear. Their ability to operate under harsh conditions, including high temperatures and heavy loads, makes them indispensable in many industries. The choice of material and design in bush bearings significantly impacts their performance, durability, and maintenance requirements, underscoring their importance in mechanical engineering.

Importance of Performance and Reliability in Bush Bearings

Performance and reliability are paramount when selecting bush bearings for any application. High-performance bush bearings can withstand greater loads, higher speeds, and more severe environmental conditions, thereby reducing downtime and maintenance costs. Reliability ensures that the bearings can consistently perform under specified conditions without failure, which is crucial for maintaining operational efficiency and safety.

Poor performance or failure of bush bearings can lead to increased friction, higher energy consumption, overheating, and potential damage to machinery, resulting in costly repairs and downtime. Therefore, understanding and comparing the performance and reliability of different bush bearing brands is vital for engineers and decision-makers in various industries.

Purpose of Comparing THK, NMB, and FAG Bush Bearings

This article aims to compare the bush bearings from three prominent manufacturers: THK, NMB, and FAG. Each of these brands has established a reputation for producing high-quality bearings, but they differ in their design philosophies, material choices, and performance characteristics. By examining these differences, we can provide insights into which brand may be best suited for specific applications.

THK is renowned for its innovation in bearing technology and its focus on precision engineering.

NMB offers a wide range of bearings known for their reliability and cost-effectiveness.

FAG is a leader in the bearing industry, known for its robust designs and high-performance bearings.

In this showdown, we will evaluate the performance and reliability of THK, NMB, and FAG bush bearings, considering factors such as load capacity, durability, ease of maintenance, and overall efficiency. By the end of this comparison, readers will have a clearer understanding of the strengths and weaknesses of each brand, helping them make informed decisions when selecting bush bearings for their specific needs.

Material Specifications

Materials Used in THK Bush Bearings

THK bush bearings are renowned for their high-quality materials, which contribute to their exceptional performance and longevity. THK typically uses a variety of materials tailored to specific applications:

High-Carbon Steel: Commonly used for its excellent strength and durability, making it ideal for heavy-duty applications.

Alloy Steels: These steels offer superior resistance to wear and fatigue, enhancing the lifespan of the bearings.

Bronze: Known for its excellent friction-reducing properties, bronze is often used in THK bearings to ensure smooth operation and lower maintenance.

Composite Polymers: For applications requiring low friction and high wear resistance, THK utilizes advanced composite polymers.

These materials are selected based on the specific demands of the application, ensuring that THK bush bearings provide optimal performance and reliability in various operating environments.

Materials Used in NMB Bush Bearings

NMB bush bearings are designed with a focus on reliability and cost-effectiveness, utilizing materials that provide a good balance of performance and affordability:

Stainless Steel: Offers excellent corrosion resistance and is commonly used in applications where exposure to moisture and chemicals is a concern.

Phosphor Bronze: This material is known for its strength and good bearing properties, often used in high-load applications.

Plastic Composites: NMB uses advanced plastic composites for lightweight applications where low friction and minimal maintenance are required.

Aluminum: In applications where weight reduction is critical, aluminum is used due to its light weight and good mechanical properties.

The selection of these materials allows NMB to produce bush bearings that are reliable, cost-effective, and suitable for a wide range of applications.

Materials Used in FAG Bush Bearings

FAG bush bearings are synonymous with robust construction and high performance, using materials that ensure durability and efficiency:

|

Material |

Description |

Applications |

|

High-Grade Steel |

Utilized for its superior strength and fatigue resistance, high-grade steel is a staple in FAG bush bearings. |

Heavy-duty and high-load applications |

|

Sintered Metals |

These metals offer excellent self-lubricating properties, reducing maintenance needs and enhancing performance. |

Applications requiring minimal maintenance |

|

PTFE (Polytetrafluoroethylene) |

Known for its extremely low friction, PTFE is used in applications requiring minimal wear and smooth operation. |

Applications needing low friction and minimal wear |

|

Ceramics |

For high-temperature and high-speed applications, FAG employs advanced ceramics known for their thermal stability and low wear rates. |

High-temperature and high-speed applications |

These materials ensure that FAG bush bearings provide exceptional performance, even in the most demanding conditions.

Comparative Analysis of Material Quality and Durability

When comparing the material specifications of THK, NMB, and FAG bush bearings, several key points emerge:

Strength and Durability: THK and FAG both use high-carbon and high-grade steels, which provide superior strength and durability. This makes them suitable for heavy-duty and high-load applications. NMB, while also using strong materials like stainless steel and phosphor bronze, tends to balance performance with cost-effectiveness.

Friction and Wear Resistance: THK’s use of bronze and composite polymers, NMB’s plastic composites, and FAG’s PTFE and ceramics highlight their focus on reducing friction and wear. FAG’s use of ceramics provides an edge in high-temperature and high-speed applications.

Corrosion Resistance: NMB’s extensive use of stainless steel offers excellent corrosion resistance, making their bearings ideal for environments with moisture and chemicals. THK and FAG also offer corrosion-resistant options but focus more on overall performance and durability.

Specialized Applications: THK and FAG’s use of advanced materials like composite polymers and ceramics positions them well for specialized applications requiring specific performance characteristics, such as low friction or high thermal stability.

In summary, each manufacturer’s choice of materials reflects their design philosophy and target applications. THK emphasizes high performance and durability with a versatile range of materials. NMB focuses on reliable and cost-effective solutions with materials that offer good all-around performance. FAG stands out for its advanced material use, particularly in demanding environments where high performance and low maintenance are critical.

Structural Features

|

Brand |

Design and Structural Features |

|

THK |

High Load Capacity: Designed to handle high loads, suitable for heavy-duty applications. |

|

|

Compact Design: Ensures space efficiency without compromising performance. |

|

|

Smooth Motion: Incorporates advanced technologies to ensure minimal friction and smooth motion, crucial for precision. |

|

|

Durable Materials: Uses high-quality materials, including advanced steel alloys and specialized coatings, enhancing durability. |

|

NMB |

Optimized Load Distribution: Ensures even load distribution, reducing stress and extending bearing life. |

|

|

Enhanced Sealing: Features superior sealing mechanisms to protect against contaminants, ensuring reliable performance. |

|

|

Precision Engineering: Emphasizes precision in manufacturing, resulting in high accuracy and consistent performance. |

|

|

Innovative Lubrication: Integrates self-lubricating materials and systems, reducing maintenance and enhancing efficiency. |

|

FAG |

Robust Construction: Built to withstand extreme conditions, offering exceptional strength and resistance to wear. |

|

|

Advanced Coatings: Applies specialized coatings to enhance corrosion resistance and wear properties. |

|

|

Customizable Designs: Provides customizable options to meet specific application requirements. |

|

|

High Precision: Ensures high precision through rigorous manufacturing standards and quality control, resulting in reliability. |

Advantages and Disadvantages of Each Brand's Design

THK:

Advantages: High load capacity, compact design, smooth motion, durable materials.

Disadvantages: May be more expensive due to advanced features and materials.

NMB:

Advantages: Optimized load distribution, enhanced sealing, precision engineering, innovative lubrication.

Disadvantages: Might require specific maintenance practices to fully benefit from self-lubricating features.

FAG:

Advantages: Robust construction, advanced coatings, customizable designs, high precision.

Disadvantages: Customizable options might lead to longer lead times for specific applications.

In conclusion, the structural features of THK, NMB, and FAG bush bearings each offer unique advantages tailored to different application needs. Understanding these features helps in making an informed decision when selecting the most suitable bush bearing for your specific requirements.

Size Range and Dimensions

|

Brand |

Miniature Bushings (ID Range) |

Large Bushings (ID Range) |

|

THK |

3 mm to 20 mm |

Exceeds 100 mm |

|

NMB |

2 mm to 25 mm |

Exceeds 150 mm |

|

FAG |

1 mm and up |

Exceeds 200 mm |

Impact of size variations on performance and applications

The size variations offered by THK, NMB, and FAG directly influence the performance and suitability of bush bearings for specific applications. Miniature bushings are favored in precision equipment where space is limited and precise motion control is essential. These smaller sizes ensure minimal friction and high efficiency, crucial for devices like robotics and semiconductor manufacturing equipment.

Conversely, larger bush bearings provided by these manufacturers are indispensable in heavy machinery such as mining equipment and construction machinery. The larger IDs enable these bearings to support substantial loads while maintaining stability and longevity. Size variations thus play a pivotal role in determining the operational efficiency, lifespan, and overall performance of bush bearings across diverse industrial applications.

Installation Guidelines

THK Bush Bearings Installation Process

Installing THK bush bearings involves a systematic approach to ensure optimal performance and longevity. Below is a detailed step-by-step guide:

Preparation:

Gather the necessary tools and equipment: torque wrench, bearing press (if applicable), cleaning solvent, and appropriate lubricant.

Ensure the shaft and housing are clean and free from debris or old lubricant residues.

Mounting Preparation:

Inspect the bush bearing and shaft for compatibility and proper fit.

Apply a thin layer of recommended lubricant to the shaft surface to facilitate smooth installation.

Installation Steps:

Position the bush bearing onto the shaft, ensuring alignment with any keyways or grooves.

Use a press or suitable installation tool to gently press the bush bearing into place. Ensure even pressure to prevent distortion.

Final Checks:

After installation, verify that the bush bearing rotates freely on the shaft without binding.

Check for any misalignment or gaps between components.

Securely tighten any fasteners according to THK's recommended torque specifications.

Common Issues:

Misalignment: Ensure precise alignment during installation to prevent premature wear or failure.

Improper Lubrication: Use the specified lubricant and apply it correctly to prevent friction-related issues.

Comparative Ease of Installation

THK bush bearings are known for their straightforward installation process, thanks to precise manufacturing tolerances and clear installation guidelines provided by the manufacturer.

This installation process ensures that THK bush bearings are installed correctly, optimizing their performance and reliability in industrial applications.

Lubrication Requirements

THK Bush Bearings Lubrication Guidelines

Proper lubrication is crucial for maximizing the performance and extending the lifespan of THK bush bearings. Here are the recommended guidelines:

Lubricant Selection:

Use high-quality lubricants specifically recommended by THK for bush bearings.

Opt for lubricants that offer high viscosity and good adhesion to ensure effective protection against wear.

Application Method:

Apply the lubricant evenly to the bearing surface and shaft interface.

Ensure thorough coverage to reduce friction and prevent metal-to-metal contact.

Frequency of Lubrication:

Follow THK's recommended lubrication schedule based on operational conditions (e.g., load, speed, environment).

Regularly inspect and replenish lubricant to maintain optimal performance.

Impact on Performance and Longevity:

Proper lubrication enhances wear resistance and operational efficiency of THK bush bearings.

Inadequate lubrication can lead to increased friction, heat buildup, and premature wear.

NMB Bush Bearings Lubrication Guidelines

NMB emphasizes specific lubrication practices to ensure reliable performance across diverse applications:

Lubricant Types:

Use lubricants with excellent thermal stability and anti-corrosion properties suitable for NMB bush bearings.

Consider lubricants that offer extended service life under varying operating conditions.

Application Technique:

Apply the lubricant uniformly to the bearing surface, taking care to cover all contact points thoroughly.

Ensure proper distribution to minimize friction and enhance operational smoothness.

Maintenance Schedule:

Adhere to NMB's recommended lubrication intervals to sustain optimal bearing performance.

Monitor lubricant levels regularly and replenish as needed to mitigate wear and maintain efficiency.

Performance Benefits:

Effective lubrication preserves NMB bush bearings' load-carrying capacity and wear resistance over prolonged use.

Improper lubrication can compromise bearing integrity, leading to reduced operational reliability.

FAG Bush Bearings Lubrication Guidelines

FAG integrates advanced lubrication strategies to support robust bearing performance in demanding environments:

Preferred Lubricants:

Select lubricants with superior load-carrying capacity and extreme pressure properties suitable for FAG bush bearings.

Opt for lubricants that offer enhanced thermal stability to withstand high operational temperatures.

Application Procedure:

Apply the lubricant evenly to the bearing surfaces, ensuring comprehensive coverage to minimize frictional losses.

Employ precision techniques to maintain lubricant integrity and prevent contamination.

Maintenance Regimen:

Follow FAG's prescribed lubrication intervals tailored to operational demands and environmental factors.

Monitor lubricant condition through periodic inspections and replenish as required to sustain optimal bearing functionality.

Longevity and Operational Efficiency:

Adequate lubrication fosters FAG bush bearings' longevity and reliable performance under varying loads and environmental conditions.

Inadequate lubrication can compromise bearing efficiency and escalate maintenance costs.

Conclusion

Proper lubrication plays a pivotal role in enhancing the performance, longevity, and reliability of bush bearings manufactured by THK, NMB, and FAG. Adhering to manufacturer-recommended lubrication guidelines ensures optimal operational efficiency and mitigates potential issues associated with friction and wear.

Conclusion

Summary of Key Findings

In this comparison of THK, NMB, and FAG bush bearings, several key findings have emerged regarding their performance and reliability:

THK: Known for precise engineering and consistent performance across a wide range of applications. THK bush bearings excel in environments requiring high precision and durability, with a robust build that ensures reliable operation under varying loads.

NMB: Offers a diverse lineup of bush bearings suitable for both miniature and heavy-duty applications. NMB bush bearings are valued for their versatility and resilience, catering to industries requiring reliable performance in challenging conditions.

FAG: Renowned for engineering excellence, FAG bush bearings stand out for their superior load-carrying capacity and resistance to extreme operating conditions. They are preferred in industrial sectors where reliability and longevity are paramount.

Final Thoughts on Strengths and Weaknesses

Each brand exhibits distinct strengths that cater to specific industrial needs:

THK excels in precision applications but may be perceived as higher cost compared to others due to its precision engineering.

NMB offers a balanced combination of performance and cost-effectiveness, making it a popular choice across diverse industries.

FAG stands out for its robustness and capability to withstand heavy loads and harsh environments, albeit potentially requiring higher initial investment.

Recommendations Based on Specific Needs and Applications

Choosing the right bush bearings depends on the specific requirements of your application:

For Precision and Durability: Opt for THK bush bearings if your application demands high precision and reliable performance under stringent conditions.

For Versatility and Cost-effectiveness: Consider NMB bush bearings, which provide a versatile solution without compromising on performance across various industrial settings.

For Heavy-duty Applications: Select FAG bush bearings for their robustness and ability to handle extreme loads and environmental conditions, ensuring long-term reliability and reduced maintenance.

FAQs: Common Questions About Bush Bearings

What are bush bearings used for?

Bush bearings, also known as plain bearings or sleeve bearings, are used to reduce friction between moving parts in machinery. They support rotating shafts and provide smooth, low-friction motion.

How do bush bearings differ from other types of bearings?

Unlike ball bearings, which use balls to reduce friction, bush bearings utilize a cylindrical sleeve (bushing) made of materials like bronze, steel, or plastics. This design offers simplicity, cost-effectiveness, and reliability in various applications.

What factors should be considered when selecting bush bearings?

Load Capacity: Choose bush bearings that can withstand the maximum load expected in your application.

Operating Speed: Consider the rotational speed and ensure the bearing can operate effectively at the required RPM.

Environmental Conditions: Evaluate factors such as temperature extremes, exposure to moisture, and chemical compatibility.

Maintenance Requirements: Assess lubrication needs and maintenance intervals to ensure prolonged bearing life.

How often should bush bearings be lubricated?

The frequency of lubrication depends on operating conditions such as load, speed, and environmental factors. Follow manufacturer recommendations for optimal lubrication intervals to prevent premature wear and ensure smooth operation.

What are the signs of bush bearing failure?

Common indicators of bush bearing failure include increased friction noise, vibration, excessive heat generation, and irregular movement of shafts. Regular inspection and monitoring can help detect early signs of wear or misalignment.

Can bush bearings be used in high-temperature applications?

Yes, bush bearings are available in materials that can withstand high temperatures, such as bronze or specialized alloys. It's essential to select bearings with appropriate heat resistance for specific operating conditions.

How can bush bearing performance be optimized?

Optimal performance of bush bearings can be achieved by:

Ensuring proper alignment and installation.

Using suitable lubricants and adhering to recommended lubrication schedules.

Monitoring operating conditions and promptly addressing any signs of wear or degradation.

Conclusion

These FAQs provide essential insights into the functionality, selection criteria, maintenance practices, and performance optimization of bush bearings. Understanding these aspects helps in making informed decisions when choosing and maintaining bush bearings for various industrial applications.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings