Home> Bearing Technology> Singapore Sealed Bearings Showdown: Multiple Brands Compared

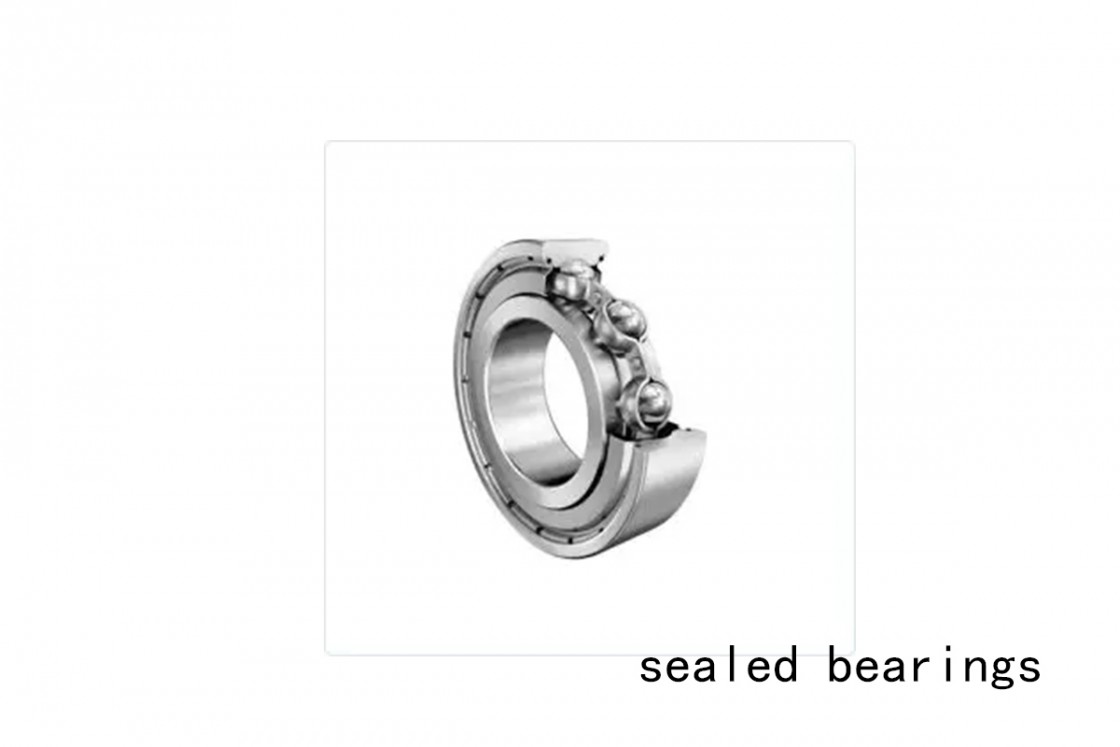

Introduction to Sealed Bearings

Sealed bearings are pivotal components within mechanical systems, designed to facilitate smooth and efficient movement by reducing friction between moving parts. They are integral to the operation of machinery across various industries, offering crucial support in applications ranging from heavy-duty manufacturing equipment to precision instruments.

Definition and Functionality

Sealed bearings are specialized types of rolling-element bearings equipped with integrated seals. These seals serve multiple functions: they keep lubricants in and contaminants out, thereby prolonging bearing life and ensuring consistent performance over time. By maintaining a barrier against dust, moisture, and other environmental factors, sealed bearings minimize wear and prevent premature failure, even in demanding operating conditions.

Importance in Industrial Applications

In industrial contexts, the reliability and performance of sealed bearings directly impact operational efficiency and maintenance costs. They are commonly employed in machinery subjected to high loads, rapid speeds, or harsh environments where conventional bearings might falter. This reliability makes them indispensable in critical applications such as conveyor systems, pumps, automotive components, and medical devices, where precision and longevity are paramount.

Overview of Sealed Bearings Market in Singapore

Singapore's vibrant industrial landscape and strategic position as a logistics and manufacturing hub underscore the significance of sealed bearings in the local market. The demand for high-quality bearings is driven by sectors such as electronics, pharmaceuticals, logistics, and precision engineering, all of which rely heavily on efficient machinery to maintain competitiveness and meet global standards.

The market offers a diverse range of sealed bearings from leading global manufacturers, catering to specific industry requirements for durability, precision, and environmental resilience. As businesses in Singapore continue to innovate and expand their operations, the role of reliable bearing solutions becomes increasingly critical in sustaining seamless production processes and enhancing overall operational efficiency.

This section provides a comprehensive introduction to sealed bearings, emphasizing their functionality, importance across industrial applications, and the dynamic market landscape in Singapore.

Material Specifications of Sealed Bearings

Sealed bearings are engineered using a variety of materials, each chosen to meet specific performance requirements and environmental conditions. Among the most commonly utilized materials are stainless steel and ceramic.

|

Characteristic |

Stainless Steel Bearings |

Ceramic Bearings |

|

Material Composition |

High-grade stainless steel |

Ceramic materials such as silicon nitride or zirconia |

|

Corrosion Resistance |

Excellent resistance to corrosion |

Highly resistant to corrosion, ideal for harsh environments |

|

Strength |

Strong and resilient |

Extremely hard and durable, capable of withstanding heavy loads |

|

Friction Coefficient |

Slightly higher compared to ceramics |

Significantly lower, reducing friction and energy losses |

|

Temperature Stability |

Good |

Excellent thermal properties, suitable for extreme temperatures |

|

Electrical Properties |

Conductive |

Non-magnetic and electrically insulating |

|

Applications |

General industrial applications, marine environments |

High-speed machinery, aerospace, electrical insulation |

|

Longevity |

Long-lasting with proper maintenance |

Extended lifespan due to wear resistance and low friction |

|

Cost |

Typically lower cost |

Higher initial cost, offset by performance benefits |

|

Weight |

Relatively heavier |

Lighter weight, reducing inertia in rotating components |

Impact of Material Choice on Performance and Longevity

The choice of material profoundly impacts the performance and longevity of sealed bearings. Stainless steel bearings excel in environments susceptible to rust and corrosion, ensuring reliable operation over extended periods. Their resilience to wear and tear minimizes maintenance requirements, making them a cost-effective solution for various industrial applications.

In contrast, ceramic bearings elevate performance metrics due to their exceptional hardness and low coefficient of friction. These properties reduce heat generation and energy consumption, prolonging operational lifespan and enhancing efficiency in critical machinery components.

Comparison of Material Standards Among Different Brands

Across different brands of sealed bearings, variations in material standards are evident, influencing their overall quality and suitability for specific applications. Major manufacturers adhere to stringent material specifications, ensuring consistency and reliability in their product offerings.

Comparison of Material Standards Among Different Brands

In the realm of precision engineering and industrial applications, sealed bearings play a pivotal role in ensuring optimal performance across various mechanical systems. The competition among different brands in Singapore offers a fascinating glimpse into the diverse approaches taken towards manufacturing these essential components.

Sealed Bearings are integral to the smooth operation of machinery, shielding critical internal components from contaminants while maintaining lubrication integrity. Understanding the nuances in material standards adopted by leading brands is crucial for making informed procurement decisions.

Material Composition and Quality Assurance

The cornerstone of any sealed bearing lies in its material composition. Brands like SKF, NTN, and Timken emphasize stringent quality control measures to ensure bearings meet or exceed industry standards. Sealed bearings, typically made from high-grade stainless steel, boast superior corrosion resistance, essential for prolonging operational lifespan in harsh environments.

Comparative Analysis: SKF vs. NTN

Let's delve deeper into the comparative material standards employed by SKF and NTN, two prominent brands in the Singapore market:

SKF Bearings: Setting the Bar High

SKF stands out for its commitment to innovation and precision. Their sealed bearings incorporate advanced ceramic balls, enhancing durability and reducing frictional losses. This innovation not only extends maintenance intervals but also optimizes operational efficiency in demanding applications such as aerospace and automotive sectors.

NTN Bearings: Engineering Excellence

NTN focuses on leveraging high-carbon chromium steel in their sealed bearings, ensuring exceptional hardness and wear resistance. This approach caters to heavy-duty industrial applications, where reliability and performance under extreme loads are paramount.

Impact of Material Standards on Performance

The choice of material directly influences the operational capabilities of sealed bearings. Brands like SKF and NTN invest heavily in research and development to fine-tune material compositions, balancing factors such as hardness, elasticity, and thermal stability. These efforts culminate in bearings capable of withstanding varying temperatures and mechanical stresses without compromising performance.

Structural Features and Design

In the competitive landscape of sealed bearings, understanding the intricate details of their structural features and design variations is crucial. This section explores the diverse approaches taken by different brands, highlighting how these nuances impact performance across various operating conditions.

Examination of Bearing Structure

Sealed bearings encompass a range of designs tailored to specific industrial needs. The two primary types—ball bearings and roller bearings—differ significantly in their construction and application suitability:

Ball Bearings: These bearings utilize spherical balls to facilitate smooth rotational motion with minimal friction. They are commonly found in applications requiring high-speed operation and moderate radial and axial loads. Ball bearings excel in scenarios where precise positioning and low starting torque are critical.

Roller Bearings: Featuring cylindrical or tapered rollers, roller bearings distribute load over a larger surface area, enhancing load capacity and durability. This design is ideal for heavy-duty applications such as conveyor systems, where handling substantial radial and axial loads is essential.

Design Innovations Across Various Brands

Each brand brings unique design innovations to the table, aiming to enhance reliability, efficiency, and longevity:

SKF's Innovations: SKF pioneers in integrating advanced seals and lubrication systems within their sealed bearings, ensuring superior contamination resistance and prolonged maintenance intervals. Their focus on precision engineering allows for customized solutions catering to diverse industry demands.

NTN's Engineering Excellence: NTN emphasizes innovative material technologies and precision manufacturing processes. Their sealed bearings feature optimized internal geometries and enhanced seal designs, enhancing operational efficiency and minimizing frictional losses across varying environmental conditions.

How Structural Differences Affect Performance in Different Conditions

The structural differences between ball bearings and roller bearings significantly influence their performance under different conditions:

Operating Conditions: In environments with varying temperatures or contaminants, the seal and lubrication systems of sealed bearings play a critical role in maintaining operational integrity. SKF's proprietary seals, for instance, offer robust protection against moisture ingress and abrasive particles, prolonging bearing life in challenging conditions.

Load Capacities: Roller bearings, due to their larger contact area and ability to accommodate heavier loads, excel in industrial applications where reliability under extreme conditions is paramount. NTN's precision-engineered roller bearings are designed to withstand high radial and axial forces, ensuring stable performance in demanding settings.

Size Range and Compatibility

In the bustling market of Singapore, sealed bearings have emerged as pivotal components across various industries, ensuring optimal performance and longevity for machinery and applications. guide navigates through the nuances of sealed bearings, comparing multiple brands to aid in informed decision-making.

Sealed bearings, essential for diverse applications in Singapore, are available in a wide range of sizes. From miniature bearings suitable for delicate instrumentation to large bearings built for heavy-duty industrial machinery, the Singapore market offers a comprehensive spectrum to cater to every need.

The importance of correct size selection cannot be overstated. Precision engineering demands precise measurements to ensure seamless operation and longevity of machinery. Choosing the right size mitigates risks of premature wear, excessive heat generation, and mechanical failure, thereby optimizing operational efficiency and reducing downtime.

Compatibility considerations are critical when integrating sealed bearings into different machinery and applications. Factors such as load-bearing capacity, rotational speed, and environmental conditions must align with the bearing's specifications to guarantee reliable performance. In Singapore's diverse industrial landscape, bearings must withstand varying temperatures, humidity levels, and operational stresses to maintain peak efficiency.

By comparing multiple brands available in the Singapore market, businesses can discern the optimal sealed bearings that meet their specific requirements. Each brand offers unique advantages in terms of material durability, precision engineering, and technological innovation, tailored to enhance performance across industries ranging from automotive manufacturing to pharmaceutical production.

Installation Guidelines

Sealed bearings are integral components in various machinery applications across Singapore, known for their ability to enhance operational reliability and minimize maintenance requirements. Understanding the step-by-step installation process is crucial to maximizing the longevity and performance of these critical components.

Step-by-Step Installation Process:

|

Step |

Description |

|

Preparation |

Begin by thoroughly cleaning the shaft and housing where the bearing will be installed. Ensure all surfaces are free of debris and contaminants. |

|

Inspect Bearings |

Before installation, inspect the sealed bearings for any signs of damage or defects. Verify that the seals are intact and undamaged. |

|

Fit and Alignment |

Carefully fit the bearing onto the shaft, ensuring proper alignment with the housing. Use precision tools as necessary for accurate positioning. |

|

Sealing and Lubrication |

Apply the manufacturer-recommended lubricant to the bearing surfaces and seals to reduce friction and heat generation during operation. |

|

Secure Housing |

Securely mount the bearing housing following manufacturer specifications for torque values of fasteners to prevent movement that could affect performance. |

Best Practices for Installing Sealed Bearings:

Follow Manufacturer Guidelines: Adhere strictly to the installation guidelines provided by the bearing manufacturer. These guidelines often include specific torque values, alignment tolerances, and lubrication requirements tailored to the bearing's design.

Temperature Control: Install bearings in environments within recommended temperature ranges to prevent thermal expansion or contraction that could affect bearing performance.

Avoid Contamination: Take precautions to prevent contamination during installation. Use clean tools and gloves to handle bearings, and protect exposed components from dust, dirt, and moisture.

Common Installation Mistakes and How to Avoid Them:

Improper Handling: Mishandling during installation can lead to bearing damage. Always use appropriate lifting and handling equipment to prevent impacts or drops.

Incorrect Fitment: Ensure bearings are correctly sized for the application and installed with proper clearances. Improper fitment can lead to excessive load on bearings and premature failure.

Over-Lubrication: Applying too much lubricant can cause overheating and compromise seal integrity. Follow recommended lubrication quantities to maintain optimal performance.

By mastering the installation process and adhering to best practices, businesses in Singapore can maximize the reliability and longevity of sealed bearings across diverse industrial applications. Stay tuned as we explore more facets of sealed bearings, including maintenance strategies and performance comparisons between leading brands.

Maintenance and Longevity

Sealed bearings are pivotal in diverse applications across Singapore, renowned for their ability to enhance operational efficiency and minimize downtime. Understanding the maintenance procedures and implementing predictive maintenance techniques are crucial steps towards maximizing their lifespan and performance.

|

Maintenance Aspect |

Description |

|

Regular Maintenance Procedures |

Proper maintenance is essential for prolonging the lifespan of sealed bearings. Conduct regular inspections to assess wear, lubrication levels, and seal integrity. Clean bearings and components to remove contaminants. |

|

Predictive Maintenance Techniques |

Implement vibration analysis and thermal imaging to detect early signs of issues. Monitor vibration patterns and thermal signatures for abnormalities. |

|

How Maintenance Practices Vary Across Brands |

Maintenance intervals and specific recommendations vary by brand, influenced by design, materials, and intended applications. Adjust schedules accordingly for optimal reliability. |

By comparing maintenance practices and longevity strategies across multiple brands, businesses can make informed decisions that align with their operational needs and budget constraints. Stay tuned as we delve deeper into the intricacies of sealed bearings, exploring performance metrics, technological innovations, and real-world applications that define their role in Singapore's dynamic industrial landscape.

Conclusion

Sealed bearings are integral components across diverse industries in Singapore, offering crucial advantages in terms of durability, efficiency, and maintenance. This section summarizes the key points discussed throughout this guide and explores future trends in sealed bearings technology, along with considerations for selecting the right brand.

Summary of Key Points Discussed:

we've highlighted the importance of sealed bearings in industrial applications, emphasizing their role in enhancing machinery performance and minimizing downtime. Key maintenance practices such as regular inspections and predictive techniques were detailed to ensure prolonged bearing lifespan and optimal operational reliability. The comparison of maintenance practices across brands underscored the importance of tailored approaches based on design, materials, and intended applications.

Future Trends in Sealed Bearings Technology:

The future of sealed bearings technology promises advancements driven by innovation in materials, lubrication techniques, and manufacturing processes. Emerging trends include the integration of smart sensors for real-time monitoring, enhanced self-lubricating materials to reduce maintenance needs, and improved sealing technologies for superior protection against contamination and harsh environments. These innovations aim to further optimize bearing performance, increase operational efficiency, and reduce lifecycle costs for industries in Singapore and beyond.

Final Thoughts on Choosing the Right Sealed Bearings Brand in Singapore:

Selecting the right sealed bearings brand in Singapore involves considering several factors beyond initial cost. It requires evaluating performance metrics, reliability records, and compatibility with specific operational environments. Brands differ in their engineering standards, customer support, and aftermarket services, influencing long-term reliability and maintenance requirements. By aligning brand selection with operational needs and industry standards, businesses can optimize performance and achieve sustainable productivity gains.

In conclusion, the dynamic landscape of sealed bearings in Singapore demands continuous adaptation to technological advancements and operational challenges. By staying informed about industry trends, leveraging advanced maintenance strategies, and choosing reputable brands, businesses can navigate this landscape with confidence, ensuring sustained success and operational excellence.

FAQs: Common Questions About Sealed Bearings

What are sealed bearings?

Sealed bearings are specialized components designed to protect against contaminants and retain lubrication within the bearing assembly. They are crucial for minimizing maintenance needs and extending the operational life of machinery in diverse industrial applications.

Why are sealed bearings important in Singapore?

In Singapore's humid and dynamic industrial environment, sealed bearings offer superior protection against moisture, dust, and debris, which can compromise conventional bearings. This reliability translates into reduced downtime and enhanced productivity for businesses across different sectors.

How do you choose the right sealed bearings brand?

Choosing the right sealed bearings brand involves considering factors such as performance metrics, durability, and compatibility with specific machinery and operational conditions. Brands vary in terms of materials used, engineering standards, and aftermarket support, impacting long-term reliability and maintenance costs.

What maintenance practices are essential for sealed bearings?

Proper maintenance is crucial for optimizing the lifespan and performance of sealed bearings. Regular inspections, lubrication checks, and cleaning procedures are fundamental to detecting early signs of wear and ensuring smooth operation. Implementing predictive maintenance techniques like vibration analysis enhances reliability by identifying potential issues before they escalate.

How do maintenance practices vary across different brands of sealed bearings?

Maintenance practices can vary based on the design, materials, and engineering standards of different sealed bearings brands. Some manufacturers may recommend specific intervals for lubrication or inspection based on the bearing's intended applications and operational environments in Singapore.

What are the future trends in sealed bearings technology?

Future trends in sealed bearings technology include advancements in materials science, such as the development of self-lubricating and corrosion-resistant materials. Innovations in sealing technologies and integration of smart sensors for condition monitoring are also enhancing reliability and efficiency in industrial applications.

Conclusion

Navigating the world of sealed bearings in Singapore involves understanding their critical role, choosing the right brand based on performance and maintenance considerations, and staying informed about technological advancements shaping the future of industrial reliability. By addressing common questions and exploring diverse aspects of sealed bearings, businesses can make informed decisions that optimize operational efficiency and durability.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings