Home> Bearing Technology> Navigating Spherical Roller Bearings in Singapore: Practical Tips and Strategies

Introduction

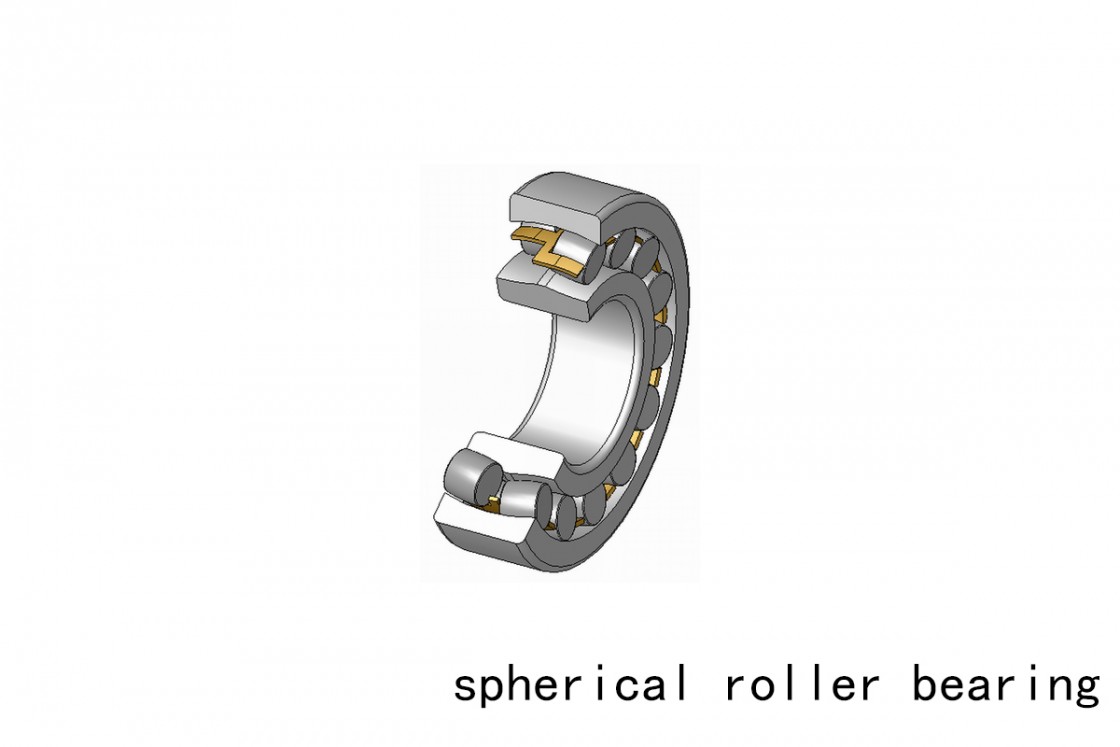

Spherical roller bearings play a pivotal role in modern industrial applications, providing robust solutions for handling both radial and axial loads with the ability to tolerate misalignment and shaft deflection. Their versatility makes them indispensable in industries such as mining, construction, and heavy manufacturing, where reliable performance under demanding conditions is paramount.

Selecting the appropriate spherical roller bearings involves careful consideration of several factors. Primary among these are load capacity, rotational speed, lubrication requirements, and environmental conditions. Each factor influences the bearing's performance and longevity, directly impacting the operational efficiency and maintenance costs of machinery.

In Singapore, a leading global hub for trade and manufacturing, the demand for high-quality spherical roller bearings is driven by stringent performance expectations and the need for operational reliability. The local market reflects a diverse array of industrial applications, ranging from marine and offshore industries to precision engineering and automotive sectors, each demanding specialized solutions tailored to specific operating environments.

Navigating the Singapore market for spherical roller bearings requires an understanding of local regulations, industry standards, and technological advancements. Businesses operating in Singapore must adhere to rigorous safety and performance standards while leveraging innovations in bearing design and materials to enhance equipment efficiency and lifespan.

explores practical tips and strategies for effectively navigating the complexities of using spherical roller bearings in Singapore. By examining best practices in selection, installation, and maintenance, businesses can optimize performance, minimize downtime, and ensure the longevity of critical machinery in various industrial sectors.

Types and Applications of Spherical Roller Bearings

Spherical roller bearings are indispensable components in modern industrial machinery, known for their ability to withstand heavy radial and axial loads while accommodating misalignment. Understanding the different types and applications of these bearings is crucial for optimizing their performance in diverse operational environments.

Types of Spherical Roller Bearings

Spherical roller bearings are categorized based on their internal construction and features, tailored to specific operational needs:

|

Type |

Description |

Applications |

|

Standard Design |

Bearings with symmetrical rollers and enhanced design for increased load capacity and durability. |

General industrial applications with moderate to heavy loads. |

|

Enhanced Load Capacity Bearings |

Bearings with optimized internal geometry and surface finishes for superior load-carrying capacity and longer service life. |

Applications requiring extended reliability under extreme conditions. |

|

Sealed and Shielded Bearings |

Bearings equipped with seals or shields to protect against contaminants and moisture ingress. |

Harsh environments such as mining, construction, and marine applications. |

Applications of Spherical Roller Bearings

The versatility of spherical roller bearings enables their deployment across a wide range of industries:

Heavy Machinery: In industries like mining and construction, spherical roller bearings support heavy equipment such as crushers, excavators, and bulldozers. They absorb shock loads and vibrations, ensuring smooth operation and minimizing downtime.

Steel Production: Rolling mills and steel processing equipment rely on spherical roller bearings to withstand high temperatures and heavy loads encountered during continuous manufacturing processes.

Automotive and Rail: Spherical roller bearings are integral to automotive wheel hubs and railway axle boxes, where they provide reliable performance under dynamic conditions and varying speeds.

Case Studies and Examples in Singapore

Singapore's strategic location and robust industrial infrastructure make it a key hub for spherical roller bearing applications:

Marine and Offshore: Offshore drilling rigs and marine vessels utilize spherical roller bearings in propulsion systems and winches. The bearings' self-aligning capability ensures operational reliability amidst challenging sea conditions.

Precision Engineering: Singapore's precision engineering sector relies on spherical roller bearings for CNC machining centers and robotic systems, where precision and repeatability are critical for maintaining product quality.

Spherical roller bearings in Singapore exemplify technological advancement and innovation in bearing design, ensuring optimal performance and durability across diverse industrial applications. Case studies underscore the importance of selecting the right bearing type and maintenance practices to maximize operational efficiency and reduce lifecycle costs.

Factors Influencing Spherical Roller Bearing Performance in Singapore

The performance of spherical roller bearings in Singapore is influenced by various factors, each playing a critical role in determining their efficiency, reliability, and longevity in industrial applications.

Environmental Factors

Environmental conditions in Singapore, characterized by high humidity and occasional exposure to salt air due to its maritime climate, pose challenges to bearing performance. Spherical roller bearings are exposed to moisture and contaminants, which can accelerate wear and corrosion if not adequately protected. Bearings used in outdoor applications or in proximity to marine environments require robust sealing mechanisms and corrosion-resistant materials to maintain optimal performance over time.

Importance of Proper Installation and Maintenance

Proper installation and maintenance procedures significantly impact the performance and lifespan of spherical roller bearings in Singapore. Correct installation ensures that bearings are aligned correctly, minimizing stress and ensuring even distribution of loads across the bearing surfaces. Regular maintenance intervals, including lubrication schedules and inspection routines, are crucial for detecting early signs of wear, misalignment, or inadequate lubrication that can lead to premature failure. Adhering to manufacturer-recommended practices and utilizing high-quality lubricants suitable for Singapore's climate conditions are essential for maximizing bearing efficiency and reliability.

Impact of Operational Conditions

The operational conditions under which spherical roller bearings operate in Singapore directly affect their lifespan and efficiency. Factors such as load magnitude, speed variations, and shock loads experienced in heavy machinery and industrial equipment can accelerate wear on bearing components. Bearings subjected to continuous operation or cyclic loading patterns must be selected based on their dynamic load ratings and fatigue resistance to withstand these demanding conditions without compromising performance.

In conclusion, optimizing the performance of spherical roller bearings in Singapore requires a holistic approach that considers environmental factors, proper installation and maintenance practices, and the operational conditions specific to each application. By addressing these factors proactively, businesses can enhance equipment reliability, minimize downtime, and extend the service life of critical machinery operating in Singapore's diverse industrial landscape.

Factors affecting the performance of spherical roller bearings in Singapore emphasize the importance of environmental considerations, proper installation and maintenance, and the impact of operating conditions on bearing efficiency and life.

Best Practices for Installation and Maintenance

Proper installation and maintenance practices are crucial for optimizing the performance and longevity of spherical roller bearings in Singapore's industrial environment. outlines essential steps and procedures to ensure efficient operation and minimal downtime.

Step-by-Step Guide to Proper Installation of Spherical Roller Bearings

Installation of spherical roller bearings should follow meticulous procedures to prevent premature wear and ensure optimal performance:

|

Step |

Description |

|

Preparation |

Inspect shaft and housing for cleanliness and proper dimensions. Remove burrs and contaminants. |

|

Mounting |

Carefully position bearing on shaft, ensuring alignment with bearing seat. Avoid excessive force. |

|

Securing |

Use correct locking arrangement (e.g., adapter sleeves) as per manufacturer guidelines. |

|

Alignment |

Align bearing to accommodate shaft deflection or misalignment using appropriate tools. |

|

Lubrication |

Implement comprehensive schedule with high-quality lubricants suitable for local conditions. |

|

Inspection |

Conduct routine inspections to detect wear, abnormal noise, or vibration. |

|

Cleaning |

Periodically clean bearing housings and surrounding areas to remove debris and contaminants. |

|

Grease vs. Oil |

Choose lubrication type based on application needs (grease for sealing, oil for high speeds). |

|

Monitoring |

Employ condition monitoring (vibration analysis, temperature monitoring) for early issue detection. |

Maintenance Schedules and Procedures

Regular maintenance is essential for prolonging the service life of spherical roller bearings:

Lubrication: Implement a comprehensive lubrication schedule using high-quality lubricants suitable for Singapore's climate and operating conditions. Monitor lubricant levels and replenish as necessary to prevent dry running or excessive heat buildup.

Inspection: Conduct routine inspections to detect early signs of wear, abnormal noise, or vibration. Inspect seals and shields for integrity and effectiveness in keeping contaminants out.

Cleaning: Periodically clean bearing housings and surrounding areas to remove debris and contaminants that could compromise bearing performance.

Importance of Lubrication and Monitoring

Proper lubrication is critical for reducing friction and wear between bearing components:

Grease vs. Oil: Choose between grease and oil lubrication based on application requirements and operational conditions. Grease provides sealing and longevity benefits, while oil allows for higher speeds and temperature variations.

Monitoring: Implement condition monitoring techniques such as vibration analysis and temperature monitoring to identify potential issues before they escalate. Utilize advanced monitoring technologies to track bearing health and performance trends.

In summary, adhering to best practices in installation and maintenance is fundamental to maximizing the reliability and efficiency of spherical roller bearings in Singapore. By following prescribed procedures and employing proactive maintenance strategies, businesses can minimize downtime, reduce operating costs, and enhance overall equipment performance in various industrial applications.

provides detailed guidance on the best practices for installing and maintaining spherical roller bearings, emphasizing their critical role in ensuring operational reliability and efficiency in Singapore's industrial landscape.

Strategies for Enhancing Bearing Reliability

Ensuring the reliability of spherical roller bearings in Singapore's industrial operations requires proactive strategies aimed at troubleshooting issues, implementing predictive maintenance, and leveraging local resources for effective bearing management.

Techniques for Troubleshooting Common Issues

Troubleshooting common issues with spherical roller bearings involves systematic diagnosis and corrective actions:

Abnormal Noise: Identify sources of abnormal noise, such as improper alignment or insufficient lubrication. Address issues promptly to prevent further damage.

Vibration Analysis: Utilize vibration analysis tools to detect potential bearing faults early. Analyze vibration patterns to pinpoint underlying causes and take corrective measures.

Temperature Monitoring: Monitor bearing temperatures regularly to identify overheating, which can indicate inadequate lubrication or excessive loads.

Implementing Predictive Maintenance Strategies

Predictive maintenance minimizes unplanned downtime and extends bearing life through proactive monitoring and preemptive actions:

|

Component |

Description |

|

Condition Monitoring |

Deploy advanced sensors and monitoring systems for real-time data collection on bearing health. Analyze data to predict maintenance needs. |

|

Lubrication Management |

Adopt automated lubrication systems or use lubrication analysis techniques to optimize usage and ensure adequate protection against wear and friction. |

|

Fault Detection |

Implement predictive analytics to detect early signs of bearing wear or failure based on performance trends and historical data. |

Training and Resources for Bearing Maintenance in Singapore

Singapore offers robust training and resources to support effective bearing maintenance practices:

Technical Workshops: Participate in workshops and seminars conducted by industry experts to enhance knowledge of bearing technologies and maintenance best practices.

Certification Programs: Pursue certifications in bearing maintenance and reliability engineering to ensure proficiency in handling complex bearing issues.

Local Support Networks: Access local networks and forums to exchange knowledge, share experiences, and stay updated on industry trends and innovations.

In summary, adopting proactive strategies for troubleshooting, predictive maintenance, and leveraging local resources enhances the reliability and performance of spherical roller bearings in Singapore's dynamic industrial environment. By investing in continuous improvement and leveraging technological advancements, businesses can optimize operational efficiency and reduce lifecycle costs associated with bearing maintenance.

Technological Advancements and Innovations

Technological advancements in spherical roller bearings have revolutionized their performance capabilities, enhancing efficiency and reliability in Singapore's industrial landscape. explores recent innovations, their impact on bearing performance, and adoption trends in the region.

Overview of Recent Advancements in Spherical Roller Bearing Technology

Recent years have witnessed significant advancements in spherical roller bearing technology, driven by innovations in materials, design, and manufacturing processes:

Advanced Materials: Manufacturers are developing bearings using high-performance materials such as advanced steels, ceramics, and polymers. These materials offer superior strength, durability, and resistance to wear and corrosion, suitable for demanding industrial applications in Singapore.

Enhanced Design Features: Modern bearings incorporate optimized internal geometries, surface finishes, and cage designs to improve load distribution, reduce friction, and enhance operational efficiency. These design enhancements contribute to extended bearing life and reduced maintenance requirements.

Sealing and Lubrication: Innovations in sealing technologies and lubrication systems ensure better contamination resistance and more effective lubricant distribution, critical for bearings operating in challenging environments like Singapore's humid climate.

How New Innovations Improve Performance and Efficiency

The integration of new technologies in spherical roller bearings brings several performance benefits:

|

Benefit |

Description |

|

Increased Load Capacity |

Advanced designs enable bearings to withstand higher loads, crucial for heavy-duty applications in Singapore's manufacturing and construction sectors. |

|

Enhanced Reliability |

Improved sealing and lubrication technologies minimize downtime by protecting against contamination and reducing frictional losses. |

|

Precision and Accuracy |

Innovations in manufacturing processes allow tighter tolerances and better control over dimensions, ensuring precise alignment and optimal performance. |

Adoption Trends of Advanced Bearing Technologies in Singapore

Singapore's industrial sector has shown a growing inclination towards adopting advanced bearing technologies:

Industry 0 Integration: Smart bearings equipped with sensors for condition monitoring and predictive maintenance are gaining traction. These technologies enable real-time data collection and analysis, facilitating proactive maintenance strategies to prevent unplanned downtime.

Environmental Sustainability: Bearings with eco-friendly lubricants and materials that reduce environmental impact are becoming more prevalent, aligning with Singapore's commitment to sustainable industrial practices.

Training and Education: Industry initiatives and training programs focus on educating engineers and technicians in the latest bearing technologies, promoting their effective implementation and maintenance across diverse industrial applications.

In conclusion, technological advancements continue to propel the evolution of spherical roller bearings, enhancing their performance, reliability, and sustainability in Singapore's industrial environment. By embracing these innovations and leveraging advanced bearing technologies, businesses can achieve operational excellence, optimize asset management, and drive competitive advantage in today's dynamic marketplace.

Lubrication Techniques for Enhanced Longevity

In the realm of spherical roller bearings, effective lubrication techniques are paramount to ensuring prolonged durability and optimal performance, especially within Singapore's diverse industrial landscape. This section explores the significance of lubrication, various types of lubricants tailored for specific applications, and recommended methods for proper maintenance.

Importance of Lubrication in Spherical Roller Bearings

Lubrication serves as a critical component in mitigating friction and wear between the rolling elements and raceways of spherical roller bearings. Key benefits include:

Friction Reduction: Minimizes heat generation and wear, thereby enhancing operational efficiency and extending bearing life expectancy.

Corrosion Prevention: Guards against moisture and contaminants that could compromise bearing integrity, crucial in Singapore's humid and challenging environments.

Energy Efficiency: Optimizes energy consumption by reducing mechanical losses associated with friction, promoting cost-effectiveness in industrial operations.

Types of Lubricants Suitable for Different Applications

Choosing the appropriate lubricant depends on specific operational requirements, including speed, load capacity, temperature variations, and environmental conditions:

Grease Lubrication:

General-Purpose Grease: Suitable for standard operating conditions with moderate speeds and intermittent usage.

High-Temperature Grease: Designed to withstand elevated temperatures encountered in applications like industrial furnaces and ovens.

Low-Temperature Grease: Formulated to maintain viscosity in colder climates, ensuring consistent performance during Singapore's cooler seasons.

Oil Lubrication:

Mineral Oil: Commonly used for general industrial applications due to its cost-effectiveness and versatility.

Synthetic Oil: Provides superior performance in extreme temperatures and harsh environments, offering extended lubrication intervals and enhanced wear protection.

Proper Lubrication Methods and Maintenance Schedules

Implementing effective lubrication practices involves meticulous attention to detail and adherence to recommended maintenance schedules:

Application Techniques:

Quantity Control: Apply the appropriate amount of lubricant based on manufacturer specifications and operational conditions to prevent over-lubrication or inadequate lubrication.

Even Distribution: Ensure uniform distribution of grease or oil across bearing surfaces to optimize performance and reduce the risk of premature wear.

Maintenance Guidelines:

Regular Inspections: Conduct routine checks to monitor lubricant condition, bearing temperature, and vibration levels, facilitating early detection of potential issues.

Replenishment Schedule: Reapply lubricants at specified intervals or when signs of lubrication degradation are observed, maintaining consistent performance and longevity.

By prioritizing effective lubrication techniques and adhering to proactive maintenance practices, industries in Singapore can enhance the reliability, efficiency, and lifespan of spherical roller bearings across diverse operational settings.

provides comprehensive insights into lubrication techniques tailored for spherical roller bearings, underscoring their pivotal role in optimizing performance and longevity within Singapore's industrial sectors.

Conclusion

In conclusion, navigating spherical roller bearings in Singapore's industrial landscape requires a strategic approach to optimize performance, reliability, and longevity. Throughout this guide, we have explored essential tips and strategies aimed at maximizing the efficiency of these critical components.

Recap of Key Points Discussed Regarding Navigating Spherical Roller Bearings in Singapore

Selection and Application: Choosing the right type of spherical roller bearings based on load requirements and environmental factors prevalent in Singapore ensures optimal performance and longevity.

Installation and Maintenance Practices: Implementing best practices in installation, such as proper alignment and adequate lubrication, coupled with regular maintenance schedules, significantly extends the service life of bearings.

Technological Advancements: Embracing recent innovations in bearing technology, including enhanced load capacity, improved reliability through advanced sealing and lubrication systems, and precision manufacturing processes, enhances operational efficiency in Singapore's diverse industrial sectors.

Predictive Maintenance: Adopting predictive maintenance strategies, such as condition monitoring and fault detection, helps prevent unexpected failures and minimizes downtime, thus maximizing uptime and productivity.

Final Thoughts on Optimizing Performance and Reliability

To achieve sustainable performance and reliability of spherical roller bearings in Singapore, continuous improvement and adaptation to evolving technologies and industry standards are paramount. Businesses should prioritize:

Education and Training: Investing in ongoing education and training programs for engineers and technicians ensures proficiency in handling and maintaining advanced bearing technologies.

Adherence to Standards: Staying updated with international standards and guidelines for bearing selection, installation, and maintenance promotes adherence to best practices and regulatory requirements.

Importance of Ongoing Education and Staying Updated with Industry Standards

As technologies and industrial processes evolve, staying informed about the latest advancements in spherical roller bearing technologies and industry trends equips businesses with the knowledge needed to make informed decisions and maintain competitive edge in the market. Continuous learning and adaptation foster innovation and efficiency across all facets of bearing management.

In summary, by implementing the practical tips and strategies discussed in this guide, businesses can navigate spherical roller bearings in Singapore effectively, ensuring enhanced performance, reliability, and operational efficiency in their industrial operations.

FAQs: Common Questions About Spherical Roller Bearings

Navigating the world of spherical roller bearings in Singapore involves understanding common queries and concerns. This section addresses frequently asked questions to provide clarity and insights into these crucial components used across various industries.

What are Spherical Roller Bearings?

Spherical roller bearings are precision-engineered components designed to accommodate high radial and axial loads in heavy-duty applications. They feature spherical-shaped rollers that enable self-alignment and enhanced operational performance, particularly in demanding environments.

How do Spherical Roller Bearings Differ from Other Bearing Types?

Unlike ball bearings that primarily handle radial loads, spherical roller bearings can manage both radial and axial loads due to their unique design. This versatility makes them suitable for applications where shaft misalignment or heavy loads are prevalent.

What Factors Should I Consider When Selecting Spherical Roller Bearings?

When choosing spherical roller bearings in Singapore, several factors should be evaluated:

Load Capacity: Ensure the bearing can handle anticipated loads, including dynamic and static loads specific to your application.

Operating Conditions: Consider environmental factors such as temperature variations, humidity levels, and exposure to contaminants.

Installation Requirements: Evaluate the shaft and housing dimensions, alignment tolerances, and mounting methods recommended by the manufacturer.

How Important is Proper Installation and Maintenance?

Proper installation and maintenance significantly impact the performance and longevity of spherical roller bearings:

Installation: Follow manufacturer guidelines for mounting, lubrication, and alignment to prevent premature wear and ensure optimal performance.

Maintenance: Implement regular inspection schedules, lubrication routines, and condition monitoring to detect potential issues early and avoid costly downtime.

What Are the Common Causes of Bearing Failure?

Common reasons for spherical roller bearing failure include inadequate lubrication, improper installation, contamination ingress, and operational overload. Addressing these factors through proactive maintenance practices helps mitigate risks and prolong bearing life.

How Can Predictive Maintenance Improve Bearing Performance?

Adopting predictive maintenance strategies, such as condition monitoring and lubrication analysis, enables early detection of potential issues. This proactive approach minimizes unexpected downtime, enhances operational efficiency, and extends the service life of spherical roller bearings.

Where Can I Find Resources for Bearing Education and Support in Singapore?

In Singapore, resources such as industry seminars, training programs, and technical support from bearing manufacturers and distributors play a vital role. These resources offer valuable insights, updates on technological advancements, and guidance on best practices for optimizing spherical roller bearing performance.

addresses common questions and provides informative answers about spherical roller bearings, tailored for the industrial environment in Singapore. Each FAQ is designed to enhance understanding and support efficient navigation of these critical components in various applications.

SKF Group. (2020). Spherical Roller Bearings: Product Catalog.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings