Home> Bearing Technology> Comparative Analysis of Spherical Roller Bearings in Singapore: Evaluating Multiple Brands

Comparative Analysis of Spherical Roller Bearings in Singapore: Evaluating Multiple Brands

NOVEMBER 02, 2022Introduction

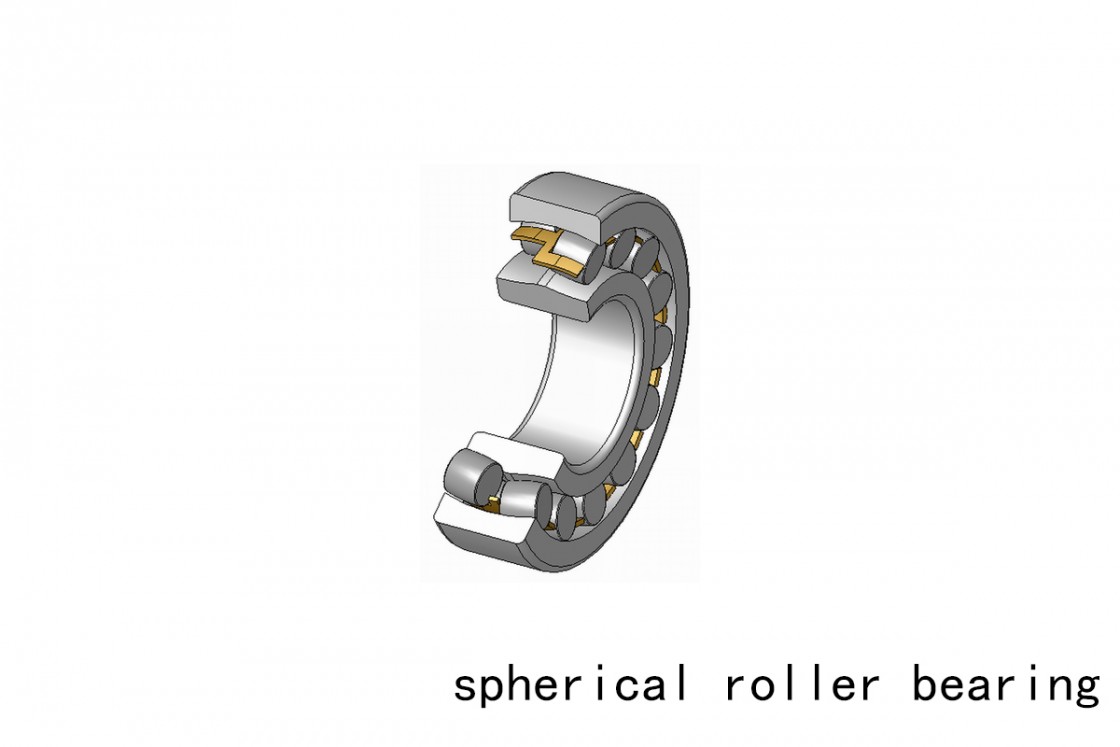

Spherical roller bearings play a pivotal role in various industrial applications across Singapore, providing crucial support for rotating machinery. Choosing the right bearing is essential to ensure optimal performance and longevity of equipment. This comparative analysis aims to evaluate multiple brands of spherical roller bearings available in the Singapore market, highlighting key differences and advantages.

Overview of Spherical Roller Bearings

Spherical roller bearings are robust and versatile components designed to accommodate high radial and axial loads in both directions. Their unique design includes two rows of symmetrical barrel rollers, which can align themselves freely in the outer ring's raceway, compensating for shaft deflections and misalignments. This feature enhances operational reliability and efficiency, making them suitable for heavy-duty applications in industries such as manufacturing, mining, construction, and transportation.

Importance of Choosing the Right Bearing for Applications in Singapore

In Singapore's industrial landscape, where precision and reliability are paramount, selecting the appropriate spherical roller bearing is crucial. Factors such as environmental conditions (humidity, temperature variations) and operational demands (speed, load capacity) must be carefully considered. A well-chosen bearing not only enhances equipment performance but also reduces maintenance costs and downtime, contributing to overall operational efficiency.

Purpose of Comparative Analysis Among Multiple Brands

The purpose of this comparative analysis is to provide a comprehensive assessment of various brands of spherical roller bearings available in Singapore. By evaluating factors such as material quality, design features, load capacities, and technological innovations, stakeholders can make informed decisions based on specific application requirements. This analysis will highlight each brand's strengths and potential limitations, aiding engineers, procurement managers, and maintenance professionals in selecting the most suitable bearing for their needs.

Material Specifications and Structural Features

Detailed Examination of Material Composition

The material composition of spherical roller bearings plays a pivotal role in determining their performance and durability in Singapore's diverse industrial settings. Bearings are primarily composed of several key materials, with steel being the predominant choice due to its exceptional strength, hardness, and ability to withstand heavy loads and harsh operating conditions.

In addition to steel, ceramic materials are increasingly used in bearing components, particularly for rolling elements and hybrid bearings. Ceramic bearings offer advantages such as higher speed capabilities, reduced friction, and resistance to corrosion and wear. Brands differ in their choice and proportion of ceramic elements, influencing factors like bearing longevity and efficiency.

Structural Design Variations Among Different Brands

The structural design of spherical roller bearings varies significantly among different brands, reflecting their engineering philosophies and technological advancements. Key structural components include the cage, inner ring, outer ring, and rolling elements. Each brand employs unique design features to optimize load distribution, reduce friction, and enhance operational reliability in Singapore's demanding applications.

For instance, brands may employ different cage materials such as brass, steel, or polyamide, each offering distinct advantages in terms of temperature resistance, lubrication retention, and noise levels. The choice of cage material is critical in environments with varying temperatures and speeds, ensuring stable performance over the bearing's lifecycle.

Impact of Material and Design on Bearing Performance in Singapore

The performance of spherical roller bearings in Singapore is directly influenced by their material composition and structural design. Bearings designed with high-quality steel and precision-engineered components exhibit superior load-bearing capabilities and resistance to fatigue, crucial for applications in heavy industries such as manufacturing, marine, and construction.

Moreover, innovative design features such as sealed or shielded bearings enhance protection against contaminants and moisture ingress, prolonging bearing life and reducing maintenance costs in humid environments typical of Singapore. Brands that integrate advanced sealing technologies provide added value by ensuring operational reliability under adverse conditions.

In conclusion, understanding the intricate details of material specifications and structural features among different brands of spherical roller bearings is essential for making informed decisions in Singapore's industrial sectors. By evaluating these factors comprehensively, stakeholders can select bearings that not only meet but exceed performance expectations, thereby optimizing equipment reliability and operational efficiency.

This section delves into the foundational aspects of spherical roller bearings, focusing on material composition, structural design variations, and their direct impact on performance in Singaporean industries.

Size Range and Installation Guidelines

Range of Available Sizes and Variants

Spherical roller bearings are available in a diverse range of sizes and variants to accommodate various industrial applications in Singapore. These bearings are categorized by their bore diameter, typically ranging from 20 mm to over 1000 mm, catering to both light-duty and heavy-duty machinery requirements. The load capacity of these bearings varies depending on their size and design, with larger bearings capable of handling significantly higher radial and axial loads.

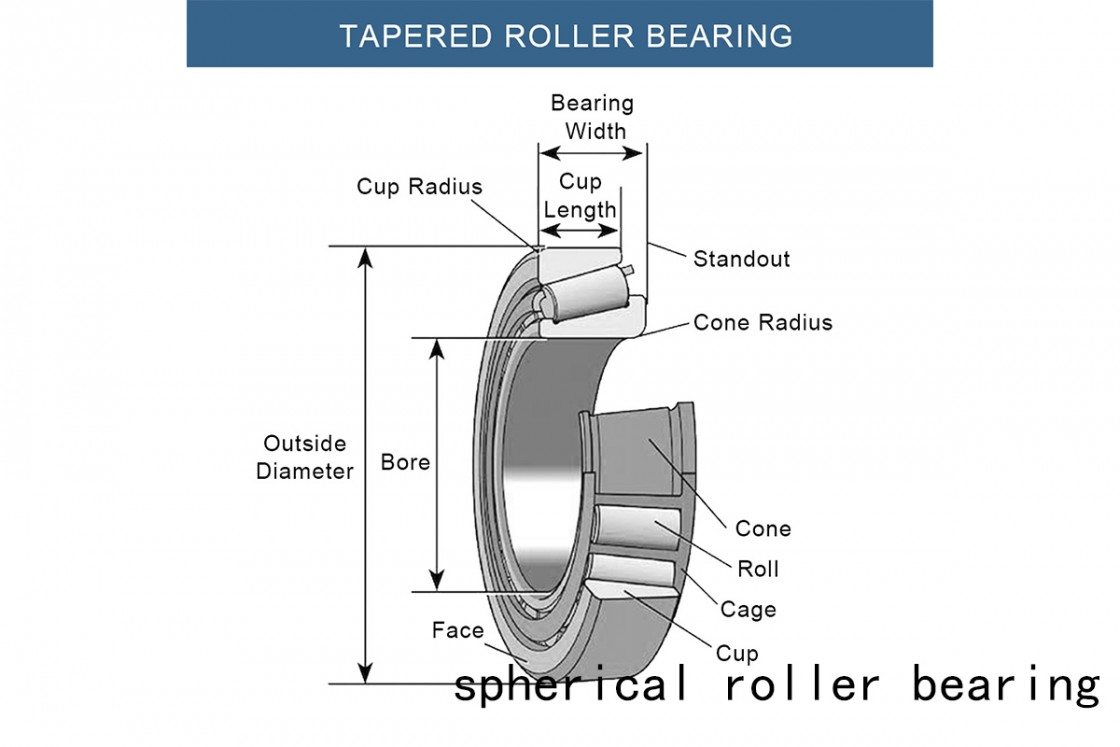

Furthermore, manufacturers offer variants such as tapered bore bearings, which facilitate easier mounting and dismounting by using tapered shafts or sleeves. This design feature is particularly advantageous in industries requiring frequent maintenance or equipment adjustments, enhancing operational flexibility and efficiency in Singapore's dynamic industrial environments.

Installation Requirements Specific to Singaporean Conditions

Proper installation of spherical roller bearings is critical to ensure optimal performance and longevity, especially in Singapore's tropical climate characterized by high humidity and temperature variations. Installation procedures must adhere to manufacturer specifications and industry standards, emphasizing cleanliness, alignment accuracy, and effective lubrication practices.

Singapore's industrial sectors, such as marine and construction, often operate in challenging conditions where bearings are exposed to contaminants and moisture. As such, bearings should be properly sealed and protected during installation to prevent premature wear and damage. Brands offering advanced sealing solutions enhance bearing reliability and durability, mitigating potential issues associated with environmental factors.

Best Practices and Guidelines for Proper Installation

To optimize the performance and lifespan of spherical roller bearings in Singapore, adherence to best practices during installation is paramount. Key guidelines include:

|

Best Practice |

Description |

|

Pre-installation inspection |

Verify bearing condition and components for signs of damage or contamination. |

|

Precision mounting |

Ensure accurate alignment and fitment of bearings to shafts and housings. |

|

Effective lubrication |

Apply correct type and amount of lubricant to facilitate smooth operation. |

|

Environmental protection |

Shield bearings from dust, moisture, and corrosive agents with appropriate sealing and coatings. |

By following these best practices, maintenance engineers and technicians in Singapore can maximize equipment reliability, minimize downtime, and extend bearing service life, ultimately optimizing operational efficiency across various industrial applications.

This section explores the critical aspects of size range and installation guidelines for spherical roller bearings, addressing their availability in diverse sizes, specific installation requirements tailored to Singaporean conditions, and recommended best practices to ensure reliable performance and longevity.

Lubrication Methods and Considerations

Types of Lubricants Suitable for Singapore's Environment

Choosing the right lubricant is crucial for maximizing the performance and lifespan of spherical roller bearings in Singapore's diverse industrial conditions. Bearings operate under varying temperatures, loads, and speeds, necessitating lubricants that offer robust protection against wear, corrosion, and contamination.

Mineral oils are commonly used in bearings due to their excellent viscosity properties and ability to withstand moderate operating temperatures. Brands often specify viscosity grades suitable for specific bearing sizes and applications, ensuring optimal lubrication effectiveness.

Synthetic lubricants offer enhanced performance in extreme conditions, including high temperatures and heavy loads. These lubricants provide superior oxidation stability, extended service life, and reduced friction, contributing to enhanced bearing efficiency and reliability in Singapore's demanding industrial sectors.

Lubrication Interval Recommendations for Each Brand

Each brand of spherical roller bearings in Singapore provides specific recommendations for lubrication intervals, aligning with operational demands and environmental factors. These intervals are determined based on factors such as bearing size, speed, load capacity, and application severity.

For instance, brands may recommend re-lubrication at regular intervals ranging from monthly to annually, depending on the bearing's operating conditions. Regular maintenance schedules ensure proper lubricant replenishment, preventing premature wear and ensuring consistent performance throughout the bearing's lifecycle.

Importance of Proper Lubrication in Bearing Longevity and Performance

Proper lubrication significantly influences the longevity and performance of spherical roller bearings in Singapore. Effective lubrication serves multiple critical functions, including:

|

Objective |

Description |

|

Reduction of friction |

Minimizes frictional resistance between bearing components, reducing energy consumption and heat generation. |

|

Wear protection |

Creates a protective film to shield bearing surfaces from wear and damage, especially under high loads and harsh conditions. |

|

Corrosion prevention |

Safeguards against moisture and chemical contaminants to maintain bearing integrity over time. |

Failure to adhere to recommended lubrication practices can lead to premature bearing failure, increased maintenance costs, and operational downtime. Therefore, maintenance personnel must follow manufacturer guidelines meticulously, employing proper lubrication techniques and monitoring lubricant condition regularly.

In conclusion, understanding the types of lubricants suitable for Singapore's environment, adhering to recommended lubrication intervals, and recognizing the critical role of proper lubrication are essential for optimizing the performance and longevity of spherical roller bearings across various industrial applications.

Maintenance Procedures and Tips

Maintenance of spherical roller bearings is essential to ensure prolonged service life and reliable operation in diverse industrial settings. Here, we explore routine maintenance practices, common issues, troubleshooting tips, and specific requirements pertinent to Singaporean industrial environments.

Routine Maintenance Practices for Spherical Roller Bearings

Effective maintenance routines are integral to maximizing the lifespan and performance of spherical roller bearings. Key practices include:

|

Maintenance Aspect |

Description |

|

Lubrication Management |

Proper lubrication with high-performance lubricants suitable for Singapore’s tropical climate. Regular lubrication intervals to prevent wear and ensure smooth operation. |

|

Inspection Protocols |

Scheduled inspection routines for early detection of issues like misalignment, excessive vibration, or abnormal noise. Use of vibration analysis and thermography for proactive maintenance. |

|

Environmental Considerations |

Challenges such as high humidity and chemical exposure require sealing solutions and corrosion-resistant coatings to safeguard bearings. |

Common Issues and Troubleshooting Tips

Despite their robust design, spherical roller bearings can encounter specific issues in operational environments. Common challenges include:

Overheating: Addressing overheating issues requires adequate lubrication, proper mounting, and alignment. Regular temperature monitoring and analysis assist in identifying root causes and implementing corrective actions promptly.

Fatigue Failure: Understanding load capacities and operating conditions is crucial to mitigate fatigue failure risks. Choosing bearings with appropriate load ratings and dynamic performance characteristics ensures longevity and reliability under varying loads.

Misalignment: Incorrect installation or assembly can lead to misalignment, causing premature wear and reduced bearing lifespan. Utilizing precision alignment tools during installation and periodic alignment checks minimizes these risks.

Maintenance Requirements Specific to Singaporean Industrial Settings

Singapore’s industrial landscape necessitates tailored maintenance approaches to address local environmental and operational challenges effectively. Key considerations include:

Tropical Climate Management: Managing bearing temperature and humidity levels through ventilation and climate control measures prevents moisture ingress and corrosion, preserving bearing integrity.

Chemical Exposure: Industrial sectors in Singapore may involve exposure to chemical contaminants. Employing chemical-resistant seals and barrier coatings enhances bearing protection against corrosive substances, ensuring sustained performance in challenging environments.

Regulatory Compliance: Adhering to local regulatory standards and industry guidelines for maintenance practices and safety protocols ensures operational compliance and enhances workplace safety.

In conclusion, maintaining spherical roller bearings in Singaporean industrial settings demands a systematic approach encompassing routine maintenance, proactive troubleshooting, and adaptation to local environmental conditions. By implementing these best practices and leveraging advanced maintenance strategies, industries can optimize bearing performance, minimize downtime, and extend equipment lifespan effectively.

Replacement Strategies and Cost Considerations

Signs Indicating the Need for Bearing Replacement

Detecting early signs of wear and deterioration is crucial for preemptive maintenance of spherical roller bearings. Key indicators include increased noise levels, vibration, overheating, and irregular performance during operation. Periodic inspections, utilizing advanced condition monitoring techniques such as vibration analysis and thermal imaging, facilitate early detection of these symptoms, allowing timely replacement before catastrophic failure occurs.

Availability of Replacement Parts from Different Brands in Singapore

Singapore boasts a robust industrial infrastructure supported by a diverse range of bearing manufacturers. Availability of genuine replacement parts from leading brands such as SKF, FAG, NTN, and Timken ensures compatibility and reliability in maintenance operations. Local distributors and authorized dealers stock a comprehensive inventory of bearings and components, providing quick access to necessary parts for efficient replacement procedures.

Cost Factors and Considerations When Opting for Replacement

When contemplating bearing replacement, several cost considerations come into play:

Initial Acquisition Costs: Comparing the initial purchase prices of bearings from different brands helps in assessing upfront expenditure.

Maintenance Costs: Evaluating long-term maintenance requirements and service intervals aids in estimating operational expenses.

Downtime Costs: Minimizing downtime through swift replacement procedures reduces potential losses in productivity and revenue.

Total Cost of Ownership: Calculating the total cost of ownership, encompassing acquisition, maintenance, and operational costs over the bearing’s lifecycle, provides a comprehensive financial perspective.

Economic Viability: Balancing quality, reliability, and cost-effectiveness is essential when selecting replacement bearings. Opting for renowned brands known for durability and performance ensures prolonged service life and minimal maintenance expenditures, thereby optimizing operational efficiency and reducing overall lifecycle costs.

In conclusion, navigating the replacement strategies and cost considerations associated with spherical roller bearings in Singapore demands a meticulous approach. By leveraging advanced condition monitoring techniques and sourcing replacement parts from reputable brands, industries can mitigate risks, enhance equipment reliability, and maintain uninterrupted operations in the dynamic industrial landscape of Singapore.

Conclusion

Summary of Comparative Findings Among Brands

The comparative analysis of spherical roller bearings across multiple brands in Singapore reveals distinct characteristics and advantages:

SKF: Known for its robust engineering and extensive range, SKF offers bearings tailored for diverse industrial applications, emphasizing durability and high load capacity.

FAG: Renowned for precision manufacturing and innovative bearing solutions, FAG bearings excel in challenging operating conditions, providing reliability and performance.

NTN: Leveraging advanced technology, NTN’s spherical roller bearings deliver superior performance in terms of efficiency and longevity, suitable for demanding environments.

Timken: With a heritage of engineering excellence, Timken bearings are recognized for their reliability and ease of maintenance, ensuring minimal downtime and operational efficiency.

Each brand excels in specific aspects such as load capacity, friction reduction, and resistance to environmental factors like humidity and corrosion, catering to the varied needs of industries in Singapore.

Recommendations for Selecting the Most Suitable Spherical Roller Bearing in Singapore

Based on the comparative findings, selecting the most suitable spherical roller bearing involves considering several key factors:

Application Requirements: Assessing the specific operating conditions and load demands to match the bearing’s load ratings and performance capabilities.

Reliability and Durability: Prioritizing brands with a proven track record for reliability, durability, and longevity to minimize maintenance costs and downtime.

Cost-Effectiveness: Balancing initial acquisition costs with long-term maintenance and operational efficiency to achieve optimal total cost of ownership.

Technical Support: Choosing brands that offer comprehensive technical support and after-sales service ensures timely assistance and maintenance expertise.

Future Trends and Developments in Spherical Roller Bearing Technology

Looking ahead, advancements in spherical roller bearing technology are poised to enhance performance and efficiency:

Advanced Materials: Integration of high-performance alloys and composite materials for improved strength, reduced weight, and enhanced wear resistance.

Smart Bearings: Implementation of sensor technology and IoT connectivity for real-time monitoring of bearing health and predictive maintenance.

Enhanced Sealing Solutions: Development of advanced sealing technologies to mitigate contamination risks and extend bearing lifespan in harsh environments.

These innovations signify a shift towards more sustainable, efficient, and intelligent bearing solutions that align with the evolving needs of Singaporean industries.

In conclusion, the comparative analysis underscores the importance of informed decision-making when selecting spherical roller bearings in Singapore. By leveraging comparative insights and considering future technological advancements, industries can optimize operational efficiency, reduce costs, and ensure reliable performance in their machinery and equipment.

FAQs: Common Questions About Spherical Roller Bearings in Singapore

What are spherical roller bearings and how do they function in industrial applications?

Spherical roller bearings are precision-engineered components designed to accommodate high radial and axial loads in heavy-duty applications. Their unique design includes spherical-shaped rollers that enable them to compensate for misalignment and shaft deflections, ensuring stable performance and prolonged service life in diverse industrial environments across Singapore.

Which factors should be considered when selecting spherical roller bearings for Singaporean industries?

When choosing spherical roller bearings in Singapore, several critical factors come into play:

Load Capacity: Assessing the bearing’s dynamic and static load ratings ensures it can withstand the operational demands without premature failure.

Environmental Conditions: Considering factors such as humidity levels, temperature variations, and chemical exposure helps select bearings with appropriate sealing solutions and corrosion-resistant coatings.

Application Specifics: Understanding the specific operational conditions and performance requirements of the equipment aids in choosing bearings that optimize efficiency and reliability.

What are the advantages of using branded spherical roller bearings from reputable manufacturers in Singapore?

Opting for branded spherical roller bearings, such as SKF, FAG, NTN, and Timken, offers several advantages:

Reliability: These brands are renowned for their quality craftsmanship and rigorous testing, ensuring consistent performance and durability.

Technical Support: Access to technical expertise and after-sales service facilitates maintenance and troubleshooting, minimizing downtime and operational disruptions.

Global Availability: Local distributors ensure quick access to replacement parts and support, enhancing operational continuity in Singapore’s industrial landscape.

How can proactive maintenance enhance the longevity and performance of spherical roller bearings in Singapore?

Implementing a proactive maintenance strategy is crucial for maximizing the lifespan and efficiency of spherical roller bearings:

Regular Lubrication: Ensuring proper lubrication with high-performance lubricants suitable for Singapore’s climate minimizes friction and wear.

Condition Monitoring: Utilizing vibration analysis and temperature monitoring helps detect early signs of potential issues, allowing for timely intervention and replacement.

Environmental Protection: Employing sealing solutions and protective coatings safeguards bearings from contaminants, preserving their integrity in challenging industrial settings.

What are the future trends and advancements expected in spherical roller bearing technology for Singaporean industries?

Looking ahead, advancements in spherical roller bearing technology are poised to enhance performance and efficiency:

Smart Bearing Technology: Integration of sensor systems for real-time monitoring and predictive maintenance.

Advanced Materials: Development of high-performance alloys and composite materials for improved durability and operational lifespan.

Energy Efficiency: Innovations aimed at reducing friction and energy consumption to optimize operational costs and sustainability.

In conclusion, understanding the nuances of spherical roller bearings and their application in Singaporean industries is essential for optimizing equipment performance and reliability. By addressing common queries and leveraging technological advancements, industries can make informed decisions to enhance operational efficiency and mitigate risks effectively.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings