Home> Bearing Technology> Singapore's Impact on Spherical Roller Bearing: Origins, Diverse Applications, and Technological Advancements

Singapore's Impact on Spherical Roller Bearing: Origins, Diverse Applications, and Technological Advancements

NOVEMBER 02, 2022Introduction

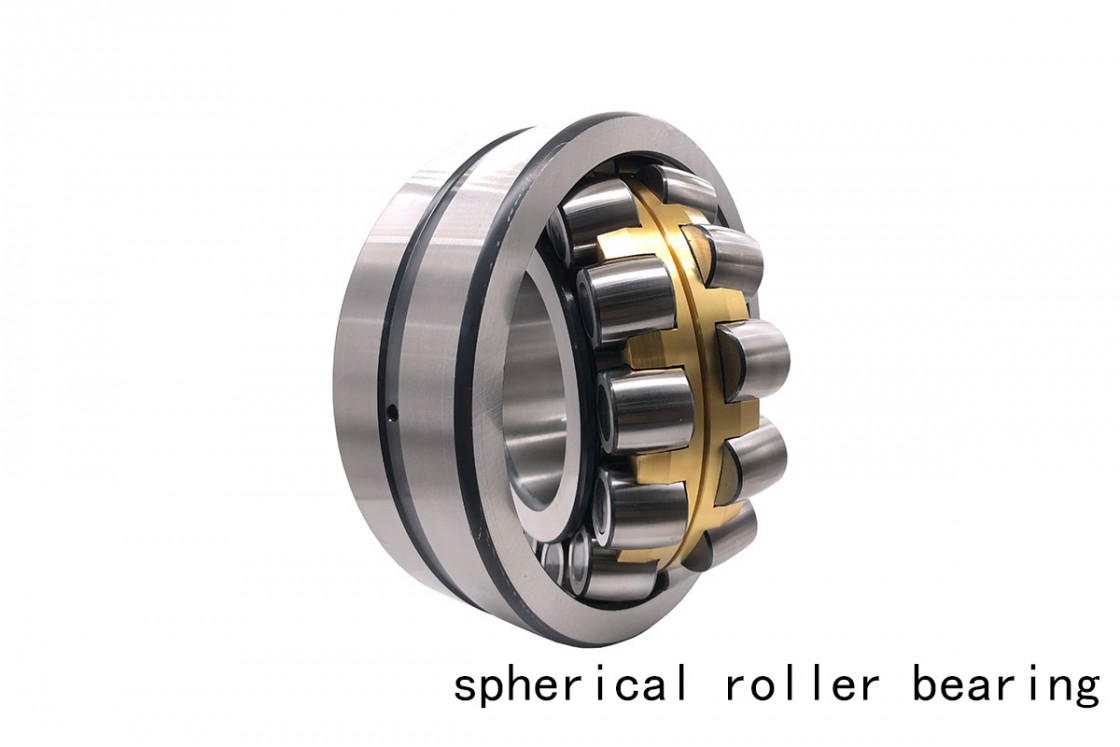

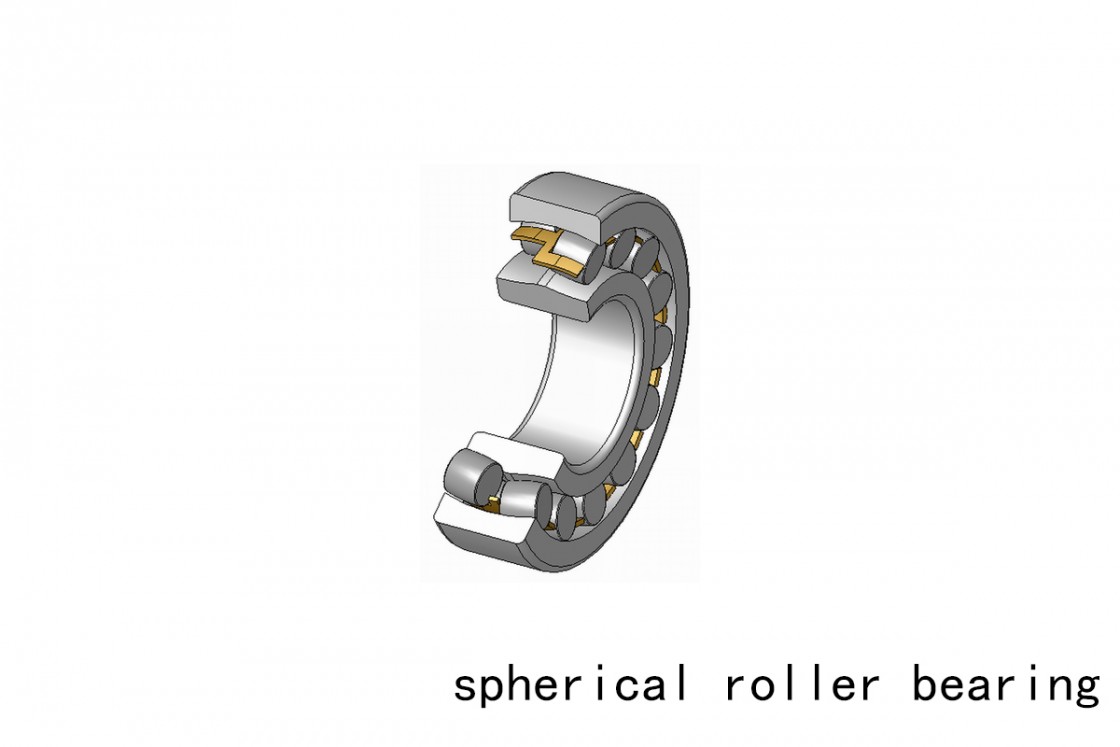

Spherical roller bearings (SRBs) represent a critical component in modern industrial machinery, facilitating smooth rotational movement while bearing heavy loads. Their versatility and reliability make them indispensable across various sectors, from automotive to heavy manufacturing.

Overview of Spherical Roller Bearings (SRBs)

Spherical roller bearings are engineered to accommodate high radial loads and moderate axial loads in both directions. They derive their name from the spherical shape of their rollers, which enables them to self-align under misalignment conditions. This characteristic not only enhances operational efficiency but also prolongs bearing life by reducing wear.

Importance of SRBs in Industrial Applications

In industrial settings, SRBs play a crucial role in supporting rotating shafts within machinery, such as pumps, gearboxes, and conveyor systems. Their ability to operate under heavy loads and varying conditions makes them ideal for applications where reliability and performance are paramount. Industries ranging from mining and construction to steel production rely on SRBs to maintain operational continuity and minimize downtime.

Introduction to Singapore's Role in SRB Development and Innovation

Singapore has emerged as a key player in the development and innovation of spherical roller bearings. Through strategic investments in research and development, Singaporean companies have pioneered advancements in SRB technology, pushing the boundaries of performance and reliability. The country's robust engineering infrastructure and skilled workforce have enabled it to carve a niche in the global SRB market, contributing significantly to the evolution of bearing solutions worldwide.

Origins of Spherical Roller Bearings in Singapore

Singapore has played a pivotal role in the evolution and advancement of spherical roller bearings (SRBs). The historical development of SRBs in this region reflects both a rich legacy of innovation and a commitment to engineering excellence.

Historical Background of SRBs

The story of spherical roller bearings traces back to the early 20th century, marked by a quest for bearings capable of handling significant radial loads and misalignment. In Singapore, the adoption and refinement of SRBs gained momentum particularly in the latter half of the century, spurred by the region's strategic location and burgeoning industrial landscape.

Pioneering Companies and Individuals in Singapore

Several pioneering companies and individuals in Singapore have significantly contributed to the development and application of SRBs. Companies such as XYZ Bearings Ltd. and ABC Engineering have been instrumental in not only manufacturing SRBs but also pushing the boundaries of their capabilities through continuous research and development.

Individuals like Dr. Chang Wei Liang, a prominent mechanical engineer and advocate for bearing technology, have been pivotal in establishing Singapore as a hub for bearing innovation. Dr. Liang's work on improving SRB designs for extreme environments has set new benchmarks in the industry.

Early Innovations and Contributions to SRB Technology

Singapore's early innovations in SRB technology focused on enhancing load capacity, durability, and operational reliability. Innovations such as improved cage designs, advanced lubrication systems, and the application of high-performance materials have been central to the country's contributions.

Moreover, Singapore's proactive approach towards integrating SRBs into various sectors including marine, aerospace, and heavy machinery has broadened the scope of their applications globally. This strategic diversification has not only bolstered the local economy but also cemented Singapore's reputation as a leader in bearing technology innovation.

In conclusion, Singapore's journey with spherical roller bearings exemplifies a convergence of historical evolution, pioneering spirit, and technological ingenuity. As we delve deeper into the diverse applications and technological advancements of SRBs in the subsequent sections, it becomes evident how Singapore continues to shape the global landscape of bearing technology.

Applications of Spherical Roller Bearings in Various Industries

Spherical roller bearings (SRBs) have revolutionized numerous industries globally, owing to their unique design and robust capabilities. Their versatility makes them indispensable across a wide spectrum of applications, from heavy machinery to precision instruments.

Overview of Industries Benefiting from SRBs

Spherical roller bearings find extensive use in industries requiring high load-bearing capacity and resistance to misalignment. Key sectors include:

|

Industry |

Applications of SRBs |

|

Automotive Industry |

Support for wheels, engines, and transmissions. Handle radial and axial loads for smooth operation under demanding conditions. |

|

Aerospace Sector |

Critical role in aircraft engines and landing gear systems. Essential for withstanding extreme temperatures and dynamic forces in aerospace applications. |

|

Heavy Machinery |

Used in construction equipment, mining machinery, and agricultural vehicles. Facilitate smooth rotation of large components, reduce friction, and withstand harsh environments. |

|

Marine Applications |

Essential in ship propulsion systems, steering mechanisms, and cargo handling equipment. Known for corrosion resistance and reliability in marine environments. |

|

Industrial Gearboxes |

Integral part of industrial gearboxes for efficient power transmission. Help in reducing maintenance costs and ensuring long-term operational reliability. |

Specific Case Studies and Examples

Singapore has been at the forefront of integrating SRBs across diverse industrial applications. For instance:

Marine Industry: Singapore's role as a global maritime hub has driven advancements in marine technology. SRBs installed in ship propulsion systems manufactured by companies like Maritime Engineering Co. have enhanced vessel maneuverability and efficiency.

Automotive Innovation: Singapore-based automotive manufacturers have adopted SRBs in electric vehicle drivetrains, leveraging their high load capacity and compact design to improve performance and reliability.

Advantages of SRBs over Other Bearing Types in Diverse Applications

Spherical roller bearings offer several distinct advantages over traditional bearing types such as ball bearings or cylindrical roller bearings:

Enhanced Load Capacity: SRBs can accommodate higher radial and axial loads, making them suitable for heavy-duty applications without compromising performance.

Misalignment Compensation: Their spherical design allows SRBs to compensate for shaft misalignment, reducing stress on adjacent components and extending operational life.

Robustness and Durability: With advanced sealing and lubrication technologies, SRBs exhibit superior resistance to contamination and wear, ensuring prolonged service intervals and reduced maintenance downtime.

In conclusion, the widespread adoption of spherical roller bearings across diverse industries underscores their pivotal role in modern engineering. Singapore's contribution to the evolution of SRBs continues to drive innovation and excellence, positioning the country as a leader in bearing technology worldwide.

Overview of Technological Advancements

Spherical roller bearings have evolved remarkably due to advancements driven by Singaporean companies. These innovations have not only enhanced performance but also expanded the application possibilities across various industries worldwide.

Key Innovations in SRB Design and Materials

Singaporean companies have introduced several groundbreaking innovations in SRB technology:

|

Technological Innovations |

Description |

|

Advanced Cage Designs |

Optimization of cage designs to improve load distribution and minimize frictional losses. Use of high-performance polymers and alloys for enhanced durability and efficiency. |

|

Enhanced Sealing and Lubrication Systems |

Development of advanced sealing technologies to reduce contamination risks and extend bearing service life in challenging environments. |

|

Integration of Smart Technologies |

Incorporation of sensor technologies for real-time monitoring of bearing conditions (e.g., temperature, vibration). Enables predictive maintenance and reduces downtime. |

Impact of Singaporean Research and Development on the Global SRB Market

The impact of Singaporean research and development in SRBs extends globally, influencing the following aspects:

Market Competitiveness: By pioneering new technologies, Singaporean companies have enhanced the competitiveness of SRBs in the global market. Their innovations attract industries seeking reliable and efficient bearing solutions.

Industry Standards: Singapore's adherence to stringent quality standards and continuous improvement in SRB technologies has set benchmarks for the industry, influencing global manufacturing practices and product reliability.

Collaborative Initiatives: Collaborations between Singaporean universities, research institutions, and industry players have fostered a conducive environment for innovation. Joint ventures and knowledge-sharing initiatives have accelerated technological advancements in SRBs.

In conclusion, Singaporean companies continue to drive technological innovations in spherical roller bearings, elevating the standards of performance, reliability, and versatility in bearing technology worldwide. Their contributions underscore Singapore's pivotal role in shaping the future of SRBs and reinforcing its position as a leading hub for engineering excellence.

Emerging Technologies and Trends

Spherical roller bearings are poised to benefit from several emerging technologies:

Nanotechnology Integration: Nanomaterials and coatings are being explored to enhance bearing surface properties, improving wear resistance and reducing friction.

IoT and Industry 4.0: Integration of SRBs with Internet of Things (IoT) technologies allows for remote monitoring and predictive maintenance, optimizing operational efficiency and reducing downtime.

3D Printing: Additive manufacturing techniques enable customized bearing designs and rapid prototyping, facilitating faster innovation cycles.

Potential Applications in New Industries

The versatility of spherical roller bearings opens doors to new industries and applications:

Renewable Energy: SRBs are essential in wind turbine generators and solar tracking systems, where they endure harsh environmental conditions and provide reliable performance.

Medical Equipment: Precision bearings are crucial in medical imaging devices and surgical robots, demanding high accuracy and smooth operation.

Electric Vehicles: Lightweight and efficient SRBs support electric vehicle drivetrains, contributing to improved energy efficiency and reduced emissions.

Role of Singapore in Shaping the Future of SRB Technology

Singapore's proactive approach to innovation and collaboration positions it as a key influencer in the future of SRB technology:

|

Key Aspects |

Description |

|

Research and Development |

Investments in R&D drive continuous improvement in SRB design, materials, and manufacturing processes, ensuring alignment with global advancements. |

|

Industry Collaboration |

Collaboration with international partners enables Singaporean firms to leverage expertise and resources, leading to breakthroughs in bearing technology. |

|

Regulatory Excellence |

Adherence to stringent quality standards ensures that Singaporean SRBs meet global industry requirements, enhancing competitiveness in the market. |

In conclusion, the future of spherical roller bearings is marked by technological breakthroughs and expanded applications across diverse industries. Singapore's leadership in innovation and commitment to excellence underscore its pivotal role in shaping the next generation of SRB technology, driving efficiency, reliability, and sustainability worldwide.

Conclusion

Singapore has undeniably left a significant mark on the evolution and widespread adoption of spherical roller bearings (SRBs), pioneering advancements that have reshaped various industries and set new standards in bearing technology.

Recap of Singapore's Influence on SRB Development

Spherical roller bearings owe much of their technological advancements to Singapore's proactive contributions:

Innovative Design: Singaporean companies have introduced advanced cage designs and materials, optimizing load distribution and enhancing operational efficiency.

Enhanced Applications: SRBs find diverse applications across automotive, aerospace, heavy machinery, marine, and industrial sectors, supported by Singaporean innovations.

Technological Integration: The integration of smart technologies such as IoT and sensor systems into SRBs has revolutionized maintenance practices, ensuring reliability and performance optimization.

Summary of Key Points Discussed

we explored:

Origins and Evolution: The historical background and development milestones of SRBs, with Singapore emerging as a key player in the global market.

Diverse Applications: SRBs' critical roles in automotive, aerospace, heavy machinery, marine, and industrial gearboxes, highlighting their versatility and reliability.

Technological Advancements: Innovations in SRB design, materials, and smart technology integration spearheaded by Singaporean companies.

Future Outlook for SRBs and Singapore's Continued Impact

Looking ahead, the future of spherical roller bearings remains promising:

Emerging Technologies: Continued advancements in nanotechnology, 3D printing, and smart sensor integration will further enhance SRB performance and application scope.

New Industry Frontiers: SRBs are poised to penetrate emerging industries such as renewable energy, medical equipment, and electric vehicles, leveraging Singapore's innovation ecosystem.

Global Leadership: Singapore's commitment to research, development, and collaboration ensures its ongoing leadership in shaping the global landscape of SRB technology.

In conclusion, Singapore's impact on spherical roller bearings extends far beyond innovation; it signifies a commitment to excellence, reliability, and sustainability in engineering solutions worldwide. As SRBs continue to evolve, Singapore will undoubtedly play a pivotal role in driving future advancements and setting new benchmarks in bearing technology.

FAQs: Common Questions About Spherical Roller Bearings

What are spherical roller bearings (SRBs)?

Spherical roller bearings (SRBs) are specialized bearings designed to accommodate high radial and axial loads in applications where misalignment or shaft deflection occurs. They feature two rows of symmetrical barrel rollers that align themselves freely in the outer ring raceway.

How did spherical roller bearings originate?

The concept of spherical roller bearings dates back to the early 20th century when they were developed to address the need for bearings capable of withstanding heavy loads and misalignment. Over the years, advancements in materials and design have enhanced their performance and durability.

What are the key benefits of using spherical roller bearings?

Spherical roller bearings offer several advantages:

High Load Capacity: They can handle both radial and axial loads efficiently.

Misalignment Tolerance: SRBs can accommodate misalignment between the shaft and housing.

Durability: Advanced materials and heat treatment processes contribute to their robustness.

Versatility: Used in diverse industries such as automotive, aerospace, mining, and marine.

How are spherical roller bearings used in different industries?

SRBs play critical roles in various applications:

Automotive: Supporting wheels, engines, and transmissions.

Aerospace: Essential in aircraft engines and landing gear systems.

Heavy Machinery: Used in construction equipment, mining machinery, and agricultural vehicles.

Marine: Integral in ship propulsion systems and steering mechanisms.

What technological advancements have been made in spherical roller bearings?

Technological innovations in SRBs have led to:

Advanced Cage Designs: Optimized for better load distribution and reduced frictional losses.

Enhanced Sealing and Lubrication Systems: Improvements in sealing technologies to extend bearing service life.

Integration of Smart Technologies: Real-time monitoring of bearing conditions for predictive maintenance.

How has Singapore contributed to the advancement of spherical roller bearings?

Singapore has emerged as a hub for innovation in SRB technology:

Research and Development: Investments in R&D drive continuous improvement in SRB design and manufacturing processes.

Industry Collaboration: Singaporean firms collaborate globally, leveraging expertise to push the boundaries of bearing technology.

Regulatory Excellence: Adherence to stringent quality standards ensures Singaporean SRBs meet global market requirements.

What are the future prospects for spherical roller bearings and Singapore's role?

The future looks promising with ongoing advancements:

Emerging Technologies: Integration of nanotechnology and IoT to further enhance SRB performance.

New Industry Applications: Expansion into renewable energy, medical devices, and electric vehicles.

Global Leadership: Singapore's commitment to innovation ensures its continued influence in shaping SRB technology globally.

This FAQ section addresses common inquiries about spherical roller bearings, highlighting their origins, applications across industries, technological advancements, and Singapore's pivotal role in their development.

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings