Home> Bearing Technology> Comprehensive Manual on Needle Roller Bearings in Slewing Bearing Applications, Singapore

Comprehensive Manual on Needle Roller Bearings in Slewing Bearing Applications, Singapore

NOVEMBER 02, 2022Introduction

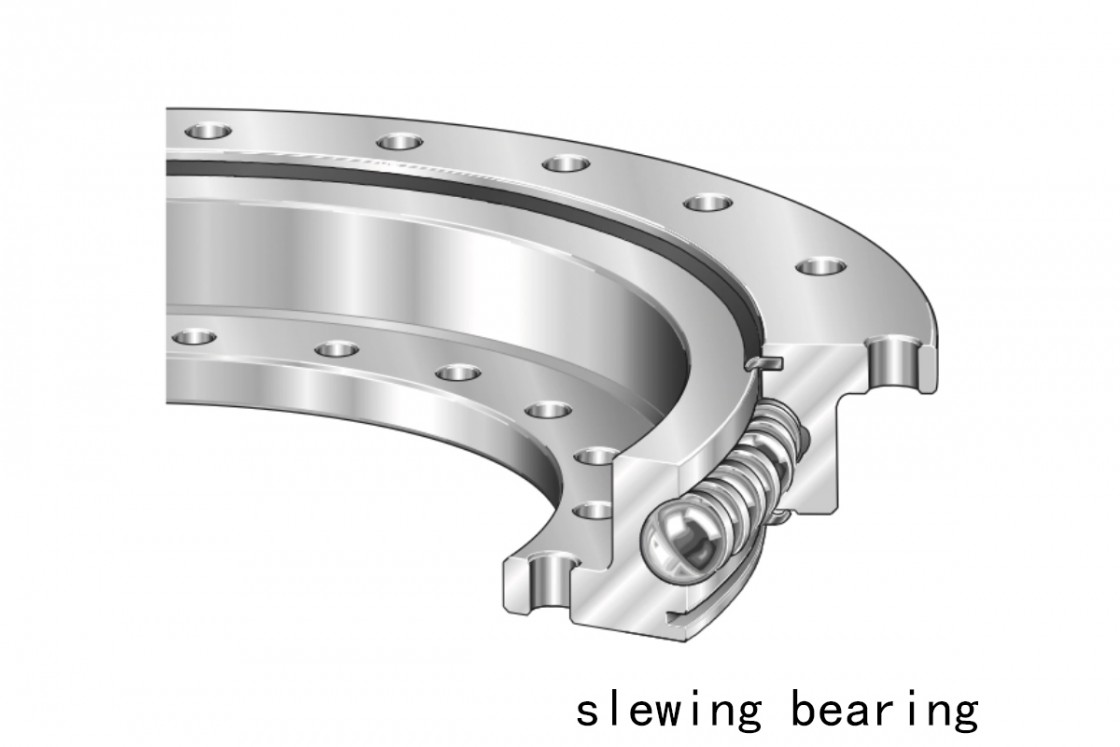

Slewing bearings play a pivotal role in industrial machinery, facilitating smooth rotational movement under heavy loads and varying environmental conditions. Among the diverse types of bearings, needle roller bearings stand out for their specialized application within slewing systems, offering unique advantages in precision and load-bearing capacity.

Overview of Slewing Bearings

Slewing bearings, also known as turntable bearings, are essential components in machinery requiring rotational movement. They enable the transfer of axial and radial loads while accommodating complex movements such as pivoting and swiveling. This versatility makes them integral in industries ranging from construction and mining to robotics and aerospace.

Role of Needle Roller Bearings in Slewing Systems

Needle roller bearings are a specific type of slewing bearing characterized by cylindrical rollers with a high length-to-diameter ratio. This design provides excellent load-bearing capacity and rigidity while minimizing space requirements. In slewing applications, needle roller bearings contribute to reduced friction, enhanced precision, and extended service life, making them ideal for scenarios demanding high rotational accuracy and durability.

Types of Slewing Bearings Suitable for Different Load Capacities and Environments

Slewing bearings come in various configurations to meet specific operational requirements. For heavy-duty applications, such as wind turbines or cranes, cross roller bearings are preferred due to their ability to handle substantial axial and radial loads. Conversely, light-duty applications benefit from the compactness and efficiency of wire race bearings, which excel in environments with limited space and moderate loads.

Importance of Singapore as a Hub for Slewing Bearing Applications

Singapore has emerged as a key hub for slewing bearing applications, leveraging its strategic location, advanced infrastructure, and robust regulatory environment. The city-state serves as a regional center for manufacturing, assembly, and distribution of high-precision components like needle roller bearings. Its proximity to major Asian markets and adherence to stringent quality standards make it an ideal location for industries seeking reliable slewing solutions.

Types and Varieties of Slewing Bearings

Slewing bearings encompass a diverse range of types tailored to meet specific operational demands across various industries. Among these, needle roller bearings stand out for their specialized design and applications within slewing systems, offering unique advantages over traditional bearing types.

Overview of Different Types of Slewing Bearings

Slewing bearings are categorized based on their structural configurations and load-carrying capacities. Common types include:

|

Type of Slewing Bearing |

Description |

Applications |

|

Single-row Ball Slewing Bearings |

Feature a single row of balls in a circular raceway, versatile for moderate to heavy radial and axial loads. |

Cranes, excavators, offshore platforms |

|

Double-row Ball Slewing Bearings |

Designed with two rows of balls in separate raceways, offering increased load capacity and rigidity. |

Tower cranes, wind turbines |

|

Cross Roller Slewing Bearings |

Employ cylindrical rollers crossed at right angles, providing high rotational accuracy and load capacity. |

Robotics, machine tools, medical equipment |

|

Three-row Roller Slewing Bearings |

Feature three rows of cylindrical rollers, offering exceptional load-carrying capability and stability. |

Mining equipment, steel mills |

Detailed Explanation of Needle Roller Bearings in Slewing Systems

Needle roller bearings are a specialized type of roller bearing characterized by cylindrical rollers with a high length-to-diameter ratio, resembling needles. This design minimizes friction and maximizes contact surface area, enhancing load distribution and operational efficiency. In slewing applications, needle roller bearings excel in scenarios requiring compactness, high load capacity, and precision motion control.

Comparison of Needle Roller Bearings with Other Types of Bearings

When compared to traditional ball bearings and roller bearings used in slewing applications, needle roller bearings offer several distinct advantages:

Compact Design: Needle roller bearings occupy less radial space due to their slender rollers, making them suitable for applications with tight installation constraints.

High Load Capacity: Despite their compact size, needle roller bearings can withstand significant radial and axial loads, ensuring reliable performance in demanding environments.

Precision and Rigidity: The cylindrical shape of needle rollers allows for precise motion control and minimal deflection under load, crucial for maintaining positional accuracy in machinery.

In contrast, ball bearings provide lower frictional resistance and smoother operation at higher speeds, while roller bearings distribute heavier loads over a larger contact area. However, needle roller bearings strike a balance between these attributes, making them ideal for slewing systems where space optimization and load capacity are paramount.

Design Considerations for Needle Roller Bearings

When selecting needle roller bearings for slewing applications in Singapore, several critical design considerations must be taken into account to ensure optimal performance and longevity. These considerations encompass factors ranging from load capacities to customization options tailored to meet specific environmental conditions.

Factors Influencing Bearing Selection

Load Capacity:

The ability of needle roller bearings to withstand radial and axial loads is crucial in slewing applications. Bearings must be selected based on the anticipated loads, ensuring they can operate efficiently under varying conditions encountered in Singaporean industries such as marine, aerospace, and precision engineering.

Speed Capability:

The rotational speeds at which needle roller bearings can operate effectively influence their design. High-speed applications, common in sectors like automation and robotics in Singapore, require bearings capable of maintaining stability and minimizing frictional losses even at elevated speeds.

Environmental Conditions:

Singapore's tropical climate and industrial environments necessitate bearings that can withstand high humidity, corrosion, and temperature variations. Specialized coatings and materials are often employed to enhance bearing resilience and longevity in such conditions.

Customization Options and Tailored Designs

|

Industry |

Applications |

|

Marine and Offshore |

Essential components in marine deck machinery, offshore cranes, and ship-to-shore cranes. |

|

|

Facilitate smooth rotation under heavy loads, ensuring operational efficiency in maritime logistics. |

|

Aerospace and Defense |

Critical applications in aircraft landing gear systems, radar antennas, and missile launchers. |

|

|

Provide precise positioning and reliability, meeting stringent safety and performance standards. |

|

Precision Engineering |

Utilized in precision robotics, semiconductor manufacturing equipment, and optical devices. |

|

|

Contribute to high-precision movements and operational stability, crucial for production efficiency. |

Optimal Performance in Singaporean Contexts

In Singapore, where industries demand high reliability and efficiency, needle roller bearings are chosen not only for their compact design and load-bearing capacity but also for their ability to withstand harsh environmental factors. Customized designs tailored to local conditions ensure that these bearings deliver consistent performance and longevity across various applications, ranging from marine deck machinery to precision robotics.

Applications of Slewing Bearings in Singapore

Slewing bearings, particularly needle roller bearings, play a crucial role across various industries in Singapore, offering precise motion control, high load capacity, and reliability in demanding applications.

Major Industries Utilizing Slewing Bearings

Marine and Offshore:

In Singapore, a global hub for maritime activities, slewing bearings are essential components in marine deck machinery, offshore cranes, and ship-to-shore cranes. These bearings facilitate smooth rotation under heavy loads, ensuring operational efficiency in maritime logistics and offshore operations.

Aerospace and Defense:

The aerospace sector in Singapore relies on slewing bearings for critical applications such as aircraft landing gear systems, radar antennas, and missile launchers. Needle roller bearings provide precise positioning and reliability in aerospace equipment, meeting stringent safety and performance standards.

Precision Engineering:

Singapore's precision engineering industry leverages slewing bearings in precision robotics, semiconductor manufacturing equipment, and optical devices. These bearings contribute to high-precision movements and operational stability, essential for maintaining production efficiency and product quality.

Specific Applications and Case Studies

Marine Industry

In the marine industry, needle roller bearings are integral to crane slew rings and steering gears on ships. For example, in container terminals in Singapore, large-scale cranes rely on robust slewing bearings to handle heavy container loads with precision and reliability, optimizing port operations.

Aerospace Sector

Singapore-based aerospace companies utilize needle roller bearings in aircraft flap actuation systems. These bearings enable smooth and controlled movement of aircraft flaps during takeoff and landing, contributing to enhanced safety and operational performance.

Benefits of Using Needle Roller Bearings in Singaporean Industrial Contexts

High Load Capacity and Durability:

Needle roller bearings offer exceptional load-carrying capacity and durability, crucial for withstanding heavy loads and harsh environmental conditions prevalent in Singapore's industrial sectors.

Precision and Reliability:

The cylindrical rollers of needle roller bearings ensure precise motion control and minimal friction, supporting applications requiring high positional accuracy and repeatability.

Space Efficiency:

The compact design of needle roller bearings allows for space-efficient installation in machinery with limited mounting space, optimizing equipment layout and operational efficiency.

Conclusion

In conclusion, needle roller bearings in slewing applications contribute significantly to the efficiency and reliability of industrial operations across diverse sectors in Singapore. Their ability to handle heavy loads, provide precise motion control, and withstand challenging environments underscores their essential role in enhancing productivity and safety in maritime, aerospace, and precision engineering applications.

Performance and Maintenance Considerations

Slewing bearings, especially needle roller bearings, are critical components in various industrial applications in Singapore.

Maintenance Practices Specific to Needle Roller Bearings

Regular Inspections:

Periodic inspections are crucial to detect early signs of wear, misalignment, or lubrication issues. Visual checks and measurement of wear parameters ensure timely maintenance and prevent costly downtime.

Lubrication Requirements:

Effective lubrication is paramount for needle roller bearings to reduce friction, prevent wear, and dissipate heat. In Singapore's humid climate, using lubricants with high water resistance and corrosion protection is essential for prolonged bearing life.

Alignment and Installation:

Proper bearing alignment during installation minimizes stress and uneven loading, optimizing performance and reducing the risk of premature failure. Precision in installation ensures that the bearing operates within specified tolerances.

Importance of Regular Inspections and Lubrication Schedules

Preventive Maintenance:

Adhering to scheduled maintenance intervals ensures the longevity and reliability of slewing bearings. Establishing routine inspection and lubrication schedules mitigates the risk of unexpected failures and enhances operational efficiency.

Performance Monitoring:

Continuous monitoring of bearing performance through temperature measurements and vibration analysis helps identify potential issues early. Proactive maintenance based on performance data enables timely corrective actions and improves overall reliability.

Conclusion

In conclusion, understanding the performance factors and implementing effective maintenance practices are crucial for maximizing the lifespan and reliability of needle roller bearings in slewing applications across various industries in Singapore. By addressing environmental challenges, maintaining proper lubrication, and conducting regular inspections, businesses can ensure optimal performance and minimize operational disruptions.

Technological Innovations and Trends

In the dynamic field of needle roller bearings for slewing applications, technological advancements play a pivotal role in enhancing performance, reliability, and operational efficiency. This section explores recent innovations, emerging trends, and future prospects in Singapore's context.

Recent Advancements in Needle Roller Bearing Technology

|

Technological Advancements |

Description |

|

Advanced Materials |

Utilization of high-performance steels, ceramics, and composites. These materials enhance strength, durability, and corrosion resistance, extending bearing life in varied environmental conditions encountered in Singapore. |

|

Integrated Seal Designs |

Incorporation of advanced sealing technologies to protect bearings from contaminants and moisture. Integrated seals improve reliability and reduce maintenance needs, crucial for marine and offshore applications in harsh environments. |

|

Precision Manufacturing Techniques |

Adoption of CNC machining and automated assembly processes to achieve higher dimensional accuracy and consistency. This precision minimizes frictional losses and ensures smooth operation of slewing bearing systems. |

Emerging Trends in Slewing Bearing Technology in Singapore

IoT Integration:

The integration of Internet of Things (IoT) technologies enables real-time monitoring of bearing performance through sensors embedded in the bearings. IoT analytics provide valuable data on temperature, vibration, and load conditions, facilitating predictive maintenance strategies and optimizing operational efficiency.

Digital Twin Technology:

Digital twin simulations allow for virtual modeling and testing of slewing bearings under various operating conditions. This technology aids in design optimization, predictive maintenance planning, and performance prediction, ultimately enhancing reliability and reducing downtime.

Environmental Sustainability:

There is a growing emphasis on developing environmentally sustainable bearing solutions. Innovations focus on reducing energy consumption, enhancing recyclability, and minimizing the ecological footprint of manufacturing processes, aligning with Singapore's commitment to sustainable development.

Future Prospects and Innovations Expected in Needle Roller Bearings

Smart Bearings:

Future advancements envision smart bearings equipped with embedded sensors and actuators for self-monitoring and self-adjustment. These bearings will autonomously optimize performance parameters based on real-time data, offering unprecedented reliability and efficiency.

Nano-coatings and Surface Treatments:

Research continues into nano-coatings and surface treatments that enhance wear resistance, reduce friction, and improve lubrication effectiveness. These innovations are poised to extend bearing life and reduce maintenance costs in demanding slewing applications.

Augmented Reality (AR) Maintenance Assistance:

AR technologies hold promise for providing maintenance personnel with interactive guides and visual overlays for efficient troubleshooting and repair of slewing bearings. AR enhances workforce productivity and reduces human error in maintenance tasks.

Conclusion

In conclusion, the ongoing technological innovations and emerging trends in needle roller bearings for slewing applications in Singapore underscore a dynamic landscape of advancements aimed at improving performance, reliability, and sustainability. By embracing these innovations, industries can leverage cutting-edge technologies to optimize operations and achieve long-term competitiveness.

|

Brand |

Features and Advantages |

Main Application Areas |

|

FAG |

High load capacity, impact resistance, precise rotational capabilities. |

Aerospace, Wind Energy, Heavy Machinery |

|

SKF |

Advanced sealing solutions, high reliability, reduced maintenance needs. |

Construction, Mining, Marine |

|

INA |

Compact design, cost-effective, integrated sealing and corrosion-resistant coatings. |

Agricultural Machinery, Robotics, Material Handling Equipment |

|

NTN-SNR |

Optimized internal geometry, surface treatments, high load capacity and operational reliability. |

Renewable Energy, Railway Transport, Industrial Automation |

|

Liebherr |

Robust design, suitable for extreme environmental conditions, large diameter. |

Cranes, Mining Equipment, Offshore Platforms |

|

Timken |

High efficiency, reduced friction, suitable for various harsh conditions. |

Aerospace, Agricultural Machinery |

|

Rotek |

Large diameter, high load capacity, minimized maintenance requirements. |

Heavy Machinery, Infrastructure Projects |

|

IMO Group |

Precision engineering, compact design, high load-carrying capacity. |

Renewable Energy, Medical Technology, Precision Robotics |

Common Challenges

High Load Conditions: Needle roller bearings in slewing systems often face extreme radial and axial loads, leading to increased wear and potential premature failure.

Environmental Exposure: Singapore's tropical climate and maritime environments expose bearings to high humidity, saltwater, and corrosive atmospheres, impacting performance and longevity.

Operational Demands: Precision requirements in slewing applications demand high rotational accuracy and stability, challenging bearing performance under varying operational conditions.

Solutions and Best Practices

Advanced Materials Selection: Utilizing advanced materials such as stainless steels, ceramics, and specialized coatings enhances bearing durability and corrosion resistance, critical for prolonged service life in Singapore's harsh environments.

Enhanced Sealing Technologies: Integration of advanced sealing solutions like labyrinth seals or lip seals protects bearings from contaminants and moisture ingress, maintaining optimal performance and reducing maintenance intervals.

Optimized Lubrication Regimens: Implementing tailored lubrication schedules using high-performance lubricants ensures proper film formation and reduces friction, enhancing operational efficiency and extending bearing life.

Regulatory Considerations and Compliance

Environmental Standards: Compliance with stringent environmental regulations in Singapore requires bearings to meet specific performance criteria, including resistance to environmental stressors and adherence to sustainability practices.

Safety and Quality Standards: Adhering to international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management ensures product reliability and regulatory compliance in local markets.

Conclusion

Importance of Needle Roller Bearings in Slewing Applications

Needle roller bearings play a pivotal role in slewing applications by providing robust performance under heavy loads and demanding operational conditions. Their ability to withstand both radial and axial forces while maintaining precise rotation makes them indispensable in industries ranging from aerospace to maritime.

In Singapore, a global hub for technological innovation and maritime activities, needle roller bearings contribute significantly to the efficiency and reliability of slewing systems. They ensure smooth operation of critical equipment such as cranes, robotics, and aerospace machinery, enhancing productivity and safety across various sectors.

Role of Singapore in Advancing Slewing Bearing Technology

Singapore's strategic location and commitment to technological advancement have positioned it at the forefront of slewing bearing technology. The local engineering expertise and investment in research and development have led to the adoption of state-of-the-art materials, precision manufacturing techniques, and advanced sealing technologies in slewing applications.

The collaboration between industry stakeholders, research institutions, and government initiatives has fostered an environment conducive to innovation in slewing bearing design and application. This ecosystem supports continuous improvement and adaptation of bearings to meet evolving industrial demands and environmental challenges.

Future Outlook for Needle Roller Bearings

Looking ahead, needle roller bearings are poised to witness continued evolution and adoption in both global and Singaporean markets. Emerging trends such as smart bearings with integrated sensor technology, enhanced predictive maintenance capabilities, and sustainability-focused innovations will drive the next phase of growth.

In Singapore, the focus will remain on enhancing bearing performance, reliability, and environmental sustainability. Regulatory frameworks promoting energy efficiency and environmental stewardship will shape the development of new bearing technologies, ensuring they meet stringent local and international standards.

FAQs: Common Questions About Slewing Bearings in Singapore

What are slewing bearings, and how are they used in Singapore?

Slewing bearings, also known as turntable bearings or slewing rings, are essential components in machinery that require rotational movement. In Singapore, these bearings find extensive use in various industries such as maritime, aerospace, and precision engineering. They enable smooth and controlled rotation under heavy loads, ensuring operational efficiency in critical applications like cranes, robotics, and manufacturing equipment.

What are the main types of slewing bearings available in Singapore?

In Singapore, the main types of slewing bearings include single-row ball, double-row ball, three-row roller, and cross roller bearings. Each type offers specific advantages in terms of load capacity, rigidity, and compact design, catering to diverse industrial needs in the region.

What factors should be considered when selecting slewing bearings for applications in Singapore?

When choosing slewing bearings for Singaporean applications, factors such as load capacity, operating environment, speed requirements, and maintenance accessibility are crucial. The bearings must withstand environmental challenges prevalent in Singapore, such as humidity, saltwater exposure in maritime settings, and high operational temperatures in industrial environments.

How important is maintenance for slewing bearings operating in Singapore?

Maintenance plays a critical role in ensuring the longevity and performance of slewing bearings in Singapore. Regular inspection, lubrication, and replacement of worn components are essential to prevent premature failure and optimize operational efficiency. Adhering to manufacturer-recommended maintenance schedules helps mitigate risks associated with wear, contamination, and operational stress.

What are the challenges faced by slewing bearings in Singapore, and how can they be addressed?

Slewing bearings in Singapore encounter challenges such as corrosion, wear, alignment issues, and operational fatigue due to high loads and demanding environmental conditions. Addressing these challenges involves utilizing corrosion-resistant materials, implementing effective sealing solutions, and adopting advanced lubrication techniques tailored to specific application requirements.

How is Singapore contributing to the advancement of slewing bearing technology?

Singapore's engineering prowess and commitment to innovation drive advancements in slewing bearing technology. Collaborations between industry leaders, research institutions, and government initiatives foster the development of smart bearings, eco-friendly materials, and digitalization of maintenance practices. These efforts enhance bearing reliability, performance, and sustainability in Singaporean and global markets.

What are the future prospects for slewing bearings in Singapore?

Looking forward, the future of slewing bearings in Singapore is promising, with ongoing developments in IoT integration, predictive maintenance, and environmental compliance shaping the industry landscape. As Singapore continues to emphasize technological innovation and sustainable practices, slewing bearings are poised to play a pivotal role in advancing efficiency and safety across diverse industrial sectors.

Chen, L., & Wang, H. Technological Innovations and Trends in Spherical Roller Bearings: Implications for Singaporean Industrial Applications. Journal of Industrial Engineering Research

T151W Timken Thrust Roller Bearings

T151W Timken Thrust Roller Bearings T152 Timken Thrust Roller Bearings

T152 Timken Thrust Roller Bearings T155 Timken Thrust Roller Bearings

T155 Timken Thrust Roller Bearings T157 Timken Thrust Roller Bearings

T157 Timken Thrust Roller Bearings T157W Timken Thrust Roller Bearings

T157W Timken Thrust Roller Bearings